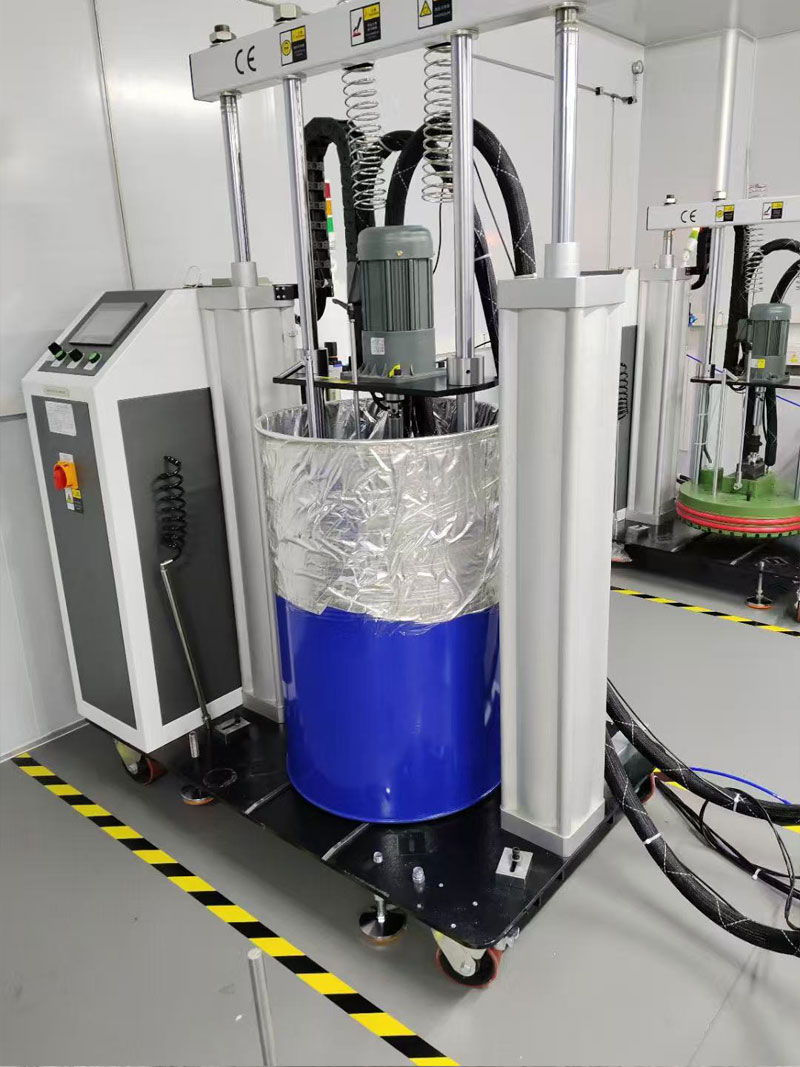

PUR 55 Gallon Double Pressure Plate Hot Melt Glue Machine

✅ PUR 55 gallon double pressure plate adhesive machine has reliable performance: mature application in the European and American markets, verified through extensive production, and guaranteed quality

✅ Double pressure plate hot melt adhesive machine reduces costs and increases efficiency: precise adhesive use reduces waste, stable operation reduces downtime losses, and increases unit time production capacity

✅ hot melt adhesive machine is worry free and adaptable: no need for frequent debugging, easy to connect with various production lines, even beginners can quickly get started

✅ hot melt adhesive machine with worry free after-sales service: providing professional installation guidance and technical support, allowing you to produce without any worries

- Saipu

- Dongguan, China

- 7-15 days

- more than 3000 sets per month

- Information

PUR 55 Gallon Double Pressure Plate Hot Melt Glue Machine

The PUR 55 Gallon Double Pressure Plate Hot Melt Glue Machine has elasticity and strength, high adhesive strength, solvent resistance, wear resistance, heat resistance, and sewing performance. It is widely used in Wood coating fitting,textiles lamination,PET transparent boxes,autoinner decoration pieces, bookbinding, household appliance assembly etc. in European and American countries. It can not only seal ordinary PVC, ABS, PP, acrylic, and high gloss edge banding, but also seal difficult to bond edge banding such as aluminum alloy.

Industrial grade design, efficient and cost-effective

Large capacity glue supply: 55 gallon super large glue bucket capacity, reducing the frequency of glue changes and improving continuous production efficiency

Stable output: The dual pressure plate design ensures uniform and stable adhesive volume, reducing the scrap rate caused by fluctuations in adhesive volume

Durable and easy to maintain: high-quality core components, wear-resistant and high-temperature resistant, extend equipment service life, and reduce maintenance costs

Excellent bonding performance and more stable quality

High elasticity and toughness: The suitable PUR hot melt adhesive combines excellent elasticity and strength, and is resistant to impact and deformation after bonding, greatly reducing the risk of product detachment

Full scene tolerance: Excellent solvent resistance, wear resistance, and heat resistance, stable performance in environments ranging from -40 ℃ to 120 ℃, and no fear of complex working conditions

Precision coating: uniform dispensing without waste, fine to 0.1mm line coating without defects, enhancing the exquisite appearance of the product

Overcoming all difficulties in adapting powerful materials

Basic materials are versatile: perfectly sealed with conventional materials such as PVC, ABS, PP, acrylic, and high gloss edge banding

Difficult to stick material killer: easily handle the sealing work of difficult to stick edge strips such as aluminum alloy, breaking the limitations of traditional equipment

Multi process compatibility: supports multiple processes such as encapsulation, lamination, binding, and assembly, and one device meets diverse production needs

System | Speed control AC motor gear pump |

Barrel diameter | ¢567mm(571mm) |

Maximum glue supply amount | 60-100kg/H/Barrel |

Output pipe | 2 line (or 4lines) |

Maximum working pressure | 70Mpa |

Operating temperature scope | 40-250℃ |

Environment temperature scope I | -20-50℃ |

Temperature control precision | ±1℃ |

Temperature sensor | Pt100/K |

Power supply | 380V3P+N(customized) |

Maximum system power | 13KW |

Air pressure applied | 0.5~0.8Mpa |

Weight | 560kg |

Connection signal | 2input,2output |

Installation size | 1450mm*1100mm*1650mm |

Level of prevention | IP54 |

Our Factory

Saipu Electromechanical Device Co., Ltd. is a company that specializes in R&D, manufacturing, marketing and after-service of hot melt glue spraying machinery. Since the date of foundation, we have devoted ourselves to satisfy market demand by making products with better performance, more completed functions and higher quality. We have established a professional team that consists of experienced technical experts and managerial staffs, which help us to achieve development based on innovative and high technology.

1

Dongguan Saipu Electromechanical Device Co., Ltd.

2

Foshan Saipu Electromechanical Device Co., Ltd.

Our Team

Our enterprise spirit is: Pursuing for high-quality and perfection, providing sincere service to customers and brand-building based on the spirit of integrity". Our operation principle is "good reputation, honest business operation and making progress together". We will satisfy our customers' needs by providing them with high quality products and careful service, and create a bright future for them.

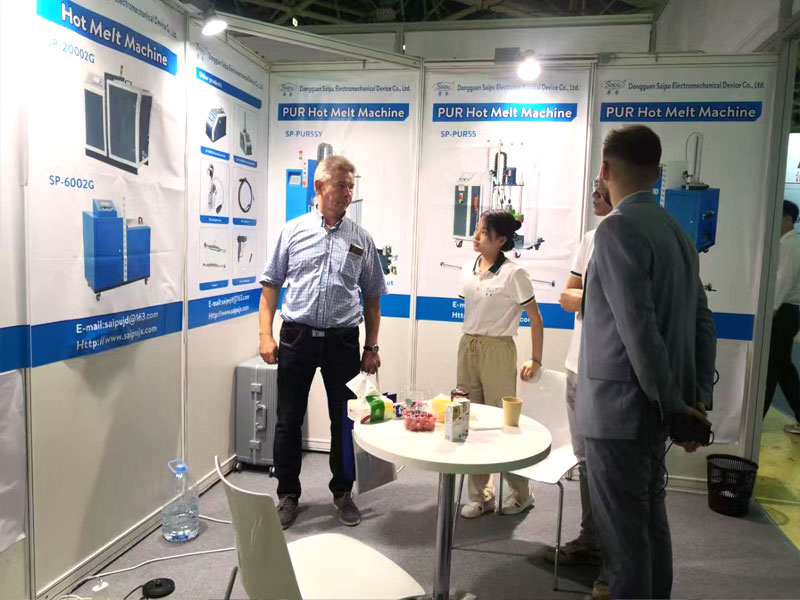

Our Exhibition

Dongguan Saipu Electromechanical Equipment Co., Ltd. is a company specializing in the research and development, manufacturing, sales, and after-sales service of hot melt adhesive spraying machinery. Saipuelectromechanical equipment has participated in many national professional exhibitions, such as Russian Woodworking Machinery Exhibition, Türkiye Woodworking Machinery Exhibition, Hanover Woodworking Machinery Exhibition, Thailand Label Exhibition, etc. Saipu Electromechanical Equipment has frequently appeared at renowned exhibitions worldwide: at the Russia Woodworking Machinery Exhibition, its hot melt adhesive spraying machines, specifically developed for the woodworking industry, attracted significant attention from local woodworking enterprises due to their efficient spraying performance and adaptability. At the Turkey Woodworking Machinery Exhibition, the company's showcased equipment, with its advanced technology and reliable performance, led to cooperative intentions with many Turkish companies. The Hannover Woodworking Machinery Exhibition in Germany, a top-tier event in the global woodworking machinery sector, saw Saipu's products fully demonstrate the strength of "Intelligent Manufacturing in China," facilitating in-depth technical exchanges and collaborations with international peers. At the Thailand Label Exhibition, the company's hot melt adhesive spraying solutions, tailored for the label industry, won widespread recognition from Southeast Asian clients by precisely meeting the special technical requirements of label production.

Through this exhibition, we not only showcased the strength of our products, but also established close connections with customers from all over the world. This is not only a recognition of our products, but also a driving force for us to continuously improve quality and optimize services in the future. We look forward to working together with these new customers and welcome more partners with needs to contact us to create a better future for cooperation.

Customer Visit

We adhere to our service objective: Credibility First and Customer First. We provide first-rate after-sales service to customers, and we make unremitting efforts to improve ourselves!

Application Scope

Our products are widely used in various sectors, including the packaging industry (carton box package, moon cake package, tea leaf box, cigarette case and beverage package), coating industry(acrylic foam tape, surgical gown, mask, mailing bags and hand bags), electronics industry(wires and cables), automobile industry(sealing materials for automobiles, car lamp manufacturing and windshield assembly), furniture industry(furniture gluing and laminating), hygienic products(disposable goods, e. g. Diapears and sanitary napkins), air filter industry, shoe-making industry, garment industry and book binding industry.

Assembly Diagram of Electrical Box

Our experienced professional team is responsible for the installation and construction of the hot melt adhesive machine. We follow industry best practices and safety standards, professional skills and knowledge to ensure a smooth and efficient installation process.

Logistics Packaging

Looking ahead to the future, Saipu Electromechanical will continue to focus on customer needs and continuously optimize our logistics system and service experience. Our mission is to help customers accelerate project development efficiently and safely - bringing Chinese made hot melt adhesive spraying machinery to farther places and making it stronger on the global stage.