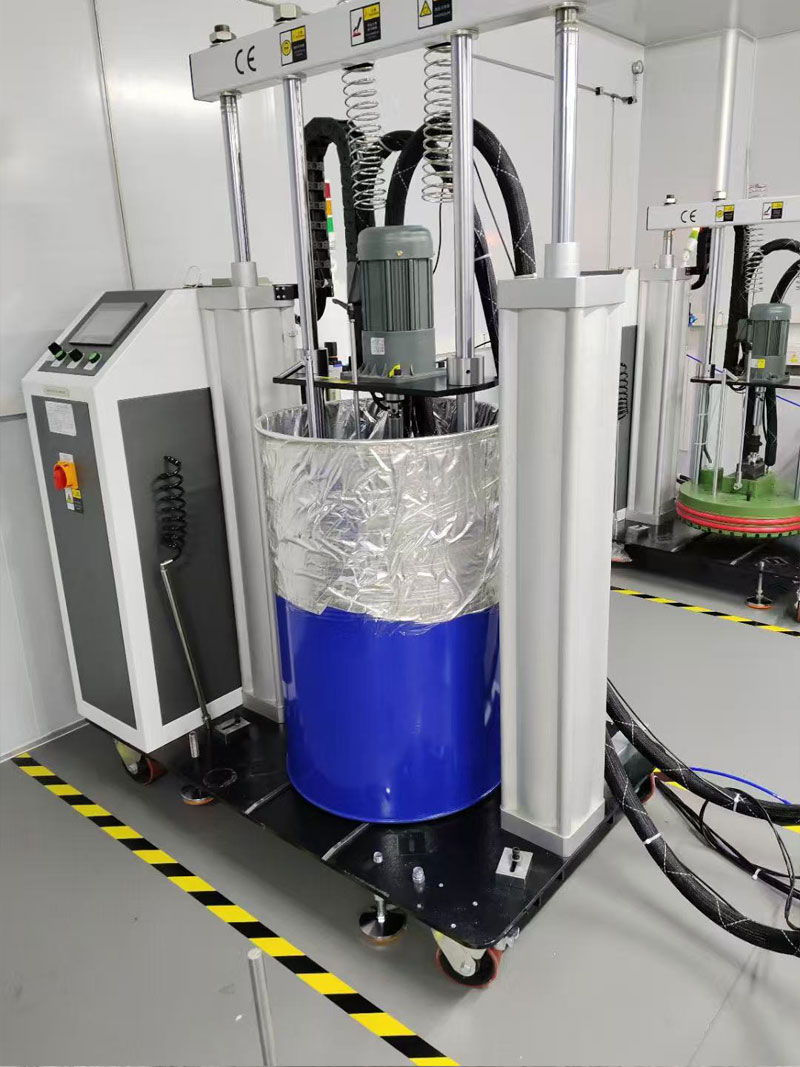

5 Gallon Hot Melt Glue Machine

Progressive Heating and Melting

The heating plate is located above the adhesive. When the heating plate is heated, only the upper layer of the adhesive in the bucket comes into contact with the heating plate and melts once reaching the melting point, while the lower part of the adhesive in the bucket remains unmelted. This achieves the requirement of melting only as much as needed during production.

Isolation from Air During Hot Melting

There is an O-ring seal between the rim of the heating plate and the inner rim of the adhesive bucket, which prevents the melted liquid adhesive from coming into contact with air. This solves the problem that adhesives like PUR cannot be exposed to air during melting.

Teflon Coating Protection

The outer surface of the heating plate is coated with Teflon, which prevents carbonization, ensures optimal adhesive quality, and reduces clogging.

- Saipu

- Dongguan, China

- 7-15 days

- more than 3000 sets per month

- Information

5 Gallon Hot Melt Glue Machine

In the field of industrial production, the performance of hot melt adhesive machines directly affects production efficiency and product quality. Our 5-gallon hot melt adhesive machine stands out among many similar products with excellent technology and advanced design, providing efficient and stable adhesive solutions for multiple industries such as woodworking wrapping and bonding, textile fabric composite, PET transparent boxes, automotive interior parts, car lights, book binding, and household appliance assembly.

1、 Core technological advantages

(1) Progressive heating melting

Adopting advanced progressive heating technology to ensure uniform heating of hot melt adhesive, the transition process from solid to liquid is smooth and steady. This heating method avoids the deterioration of the adhesive caused by local overheating, effectively improves the performance of the adhesive, and enables the adhesive to maintain good fluidity and viscosity during coating, ensuring the bonding quality of the product.

(2) During hot melting, the glue is isolated from the air

A sealing structure has been specially designed for adhesives that are sensitive to air, such as PUR. An O-ring seal is installed between the groove of the heating plate and the inner ring of the glue bucket, ensuring that the melted liquid glue does not come into contact with air at all. This perfectly solves the problem of the adhesive reacting and affecting its performance due to contact with air during the melting process, ensuring that the adhesive is always in its optimal state.

2、 Humanized functional design

(1) Stepless adjustment of adhesive output

Equipped with advanced variable speed motors and pumps that can adapt to various flow rates, and driven by an AC motor through a frequency converter to drive a gear pump for glue supply, achieving stepless adjustment of glue volume. Whether it is micro coating or large-scale adhesive production needs, it can be precisely controlled to meet the diverse requirements of different products and processes for adhesive quantity, effectively avoiding adhesive waste and improving production flexibility and accuracy.

(2) The operation of the main motor is humanized and has protective functions

The main motor adopts a humanized design, running smoothly and with low noise, creating a relatively comfortable working environment for operators. At the same time, the motor has comprehensive protection functions. When the equipment experiences abnormal situations such as overload or overheating, it can automatically trigger the protection mechanism, stop running, avoid motor burnout and other serious faults, ensure safe and reliable operation of the equipment, and extend the overall service life of the equipment.

(3) Glue shortage alarm function

Built in high-precision position sensor, real-time monitoring of the position of the pressure plate in the rubber drum. Once the glue level is too low or the glue bucket is about to be emptied, the sensor immediately triggers the glue shortage alarm function, promptly notifying the operator to replenish the glue, avoiding production interruption caused by glue shortage, ensuring the continuity of the production process, and improving production efficiency.

System | Speed control AC motor gear pump |

Barrel diameter | ¢280mm(286mm) |

Maximum glue supply amount | 20kg/H |

Output pipe | 1 line (or 4lines) |

Maximum working pressure | 8.5Mpa |

Operating temperature scope | (RT)-250℃ |

Environment temperature scope I | -20-50℃ |

Temperature control precision | ±1℃ |

Temperature sensor | Pt100/K |

Power supply | 220V |

Maximum system power | 3.5KW |

Air pressure applied | 0.5~0.8Mpa |

Weight | 195kg |

Connection signal | 2input,2output |

Installation size | (L)1030x(W)550x(H)1450mm |

Level of prevention | IP54 |

Our Factory

Saipu Electromechanical Device Co., Ltd. is a company that specializes in R&D, manufacturing, marketing and after-service of hot melt glue spraying machinery. Since the date of foundation, we have devoted ourselves to satisfy market demand by making products with better performance, more completed functions and higher quality. We have established a professional team that consists of experienced technical experts and managerial staffs, which help us to achieve development based on innovative and high technology.

1

Dongguan Saipu Electromechanical Device Co., Ltd.

2

Foshan Saipu Electromechanical Device Co., Ltd.

Our Team

Our enterprise spirit is: Pursuing for high-quality and perfection, providing sincere service to customers and brand-building based on the spirit of integrity". Our operation principle is "good reputation, honest business operation and making progress together". We will satisfy our customers' needs by providing them with high quality products and careful service, and create a bright future for them.

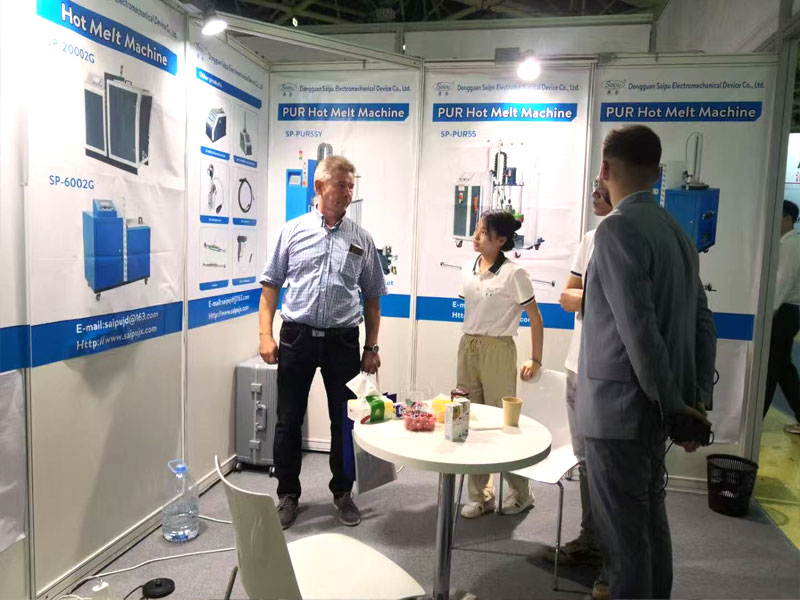

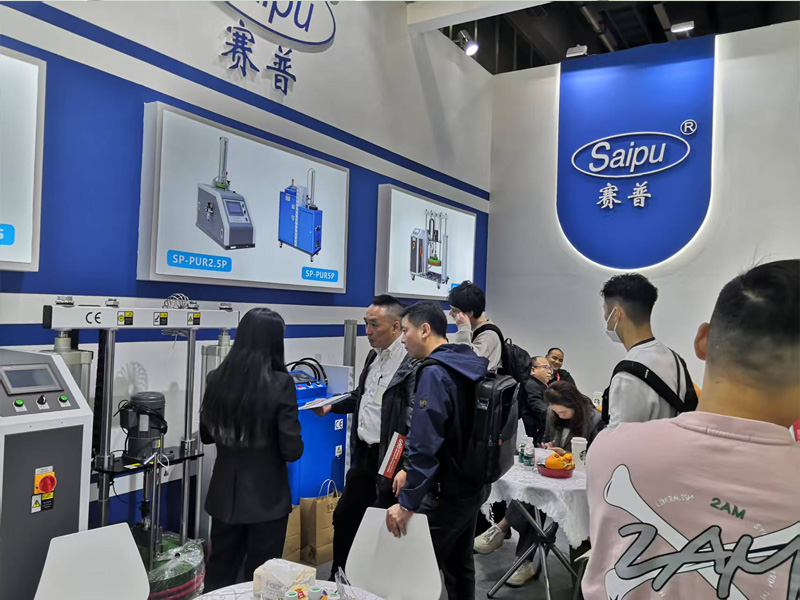

Our Exhibition

Dongguan Saipu Electromechanical Equipment Co., Ltd. is a company specializing in the research and development, manufacturing, sales, and after-sales service of hot melt adhesive spraying machinery. Saipu electromechanical equipment has participated in many national professional exhibitions, such as Russian Woodworking Machinery Exhibition, Türkiye Woodworking Machinery Exhibition, Hanover Woodworking Machinery Exhibition, Thailand Label Exhibition, etc.. At the exhibition site, our hot melt adhesive machine attracted the attention of many customers with its excellent performance and reliable quality. From the completion of booth construction and the placement of product displays, a continuous stream of customers came to inquire. They raised questions about the operational efficiency, applicable scenarios, and ease of operation of the equipment, and our staff patiently answered them one by one, detailing the core advantages of the product.

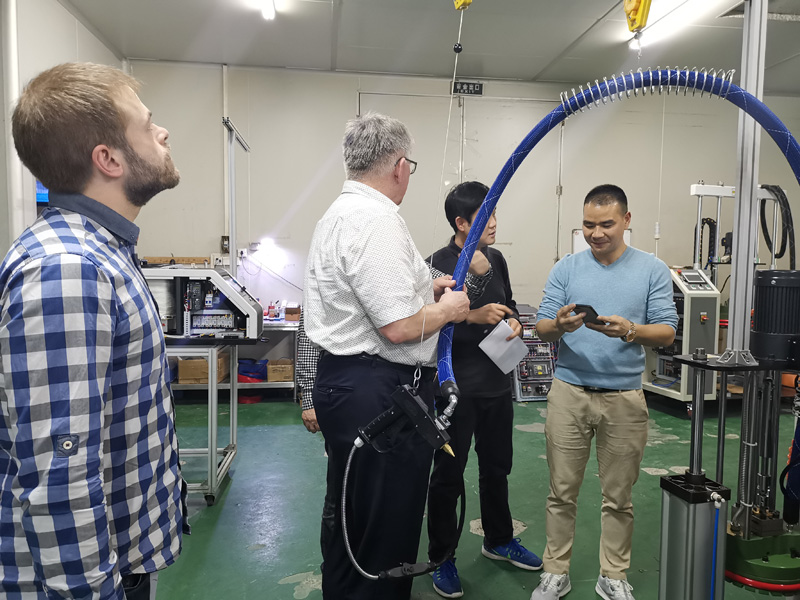

Customer Visit

We adhere to our service objective: Credibility First and Customer First. We provide first-rate after-sales service to customers, and we make unremitting efforts to improve ourselves!

Application Scope

Our products are widely used in various sectors, including the packaging industry (carton box package, moon cake package, tea leaf box, cigarette case and beverage package), coating industry(acrylic foam tape, surgical gown, mask, mailing bags and hand bags), electronics industry(wires and cables), automobile industry(sealing materials for automobiles, car lamp manufacturing and windshield assembly), furniture industry(furniture gluing and laminating), hygienic products(disposable goods, e. g. Diapears and sanitary napkins), air filter industry, shoe-making industry, garment industry and book binding industry.

Assembly Diagram of Electrical Box

Our experienced professional team is responsible for the installation and construction of the hot melt adhesive machine. We follow industry best practices and safety standards, professional skills and knowledge to ensure a smooth and efficient installation process.

Logistics Packaging

Looking ahead to the future, Saipu Electromechanical will continue to focus on customer needs and continuously optimize our logistics system and service experience. Our mission is to help customers accelerate project development efficiently and safely - bringing Chinese made hot melt adhesive spraying machinery to farther places and making it stronger on the global stage.