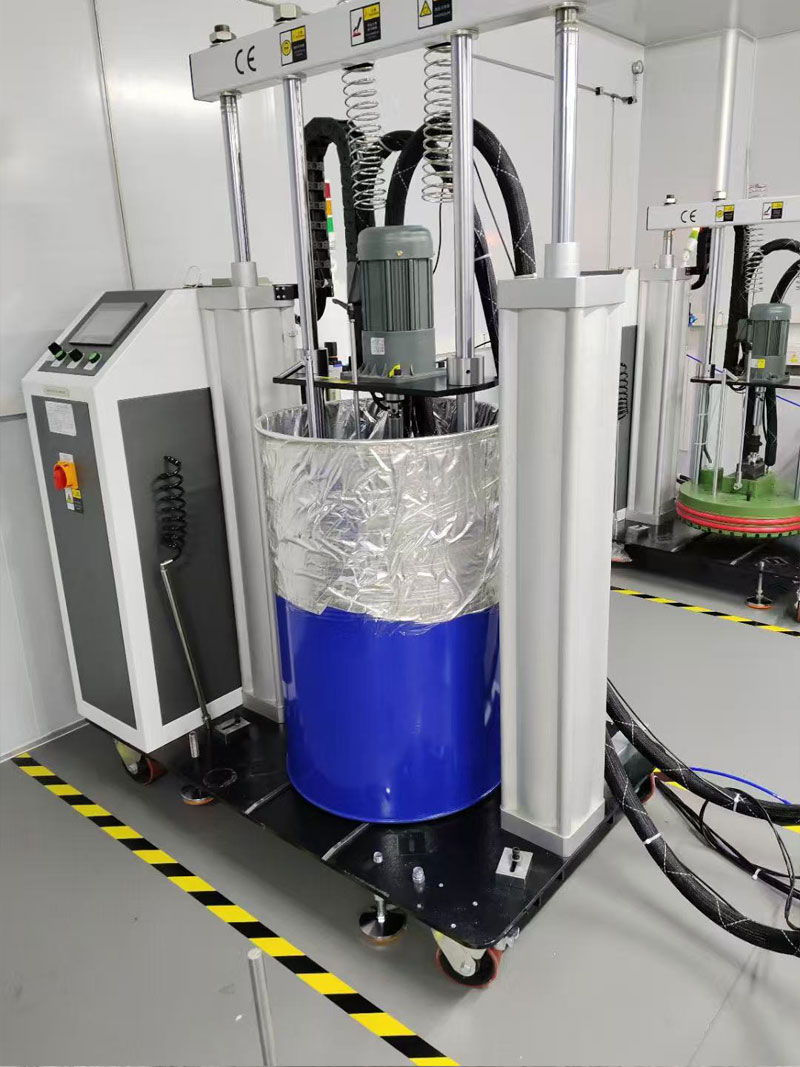

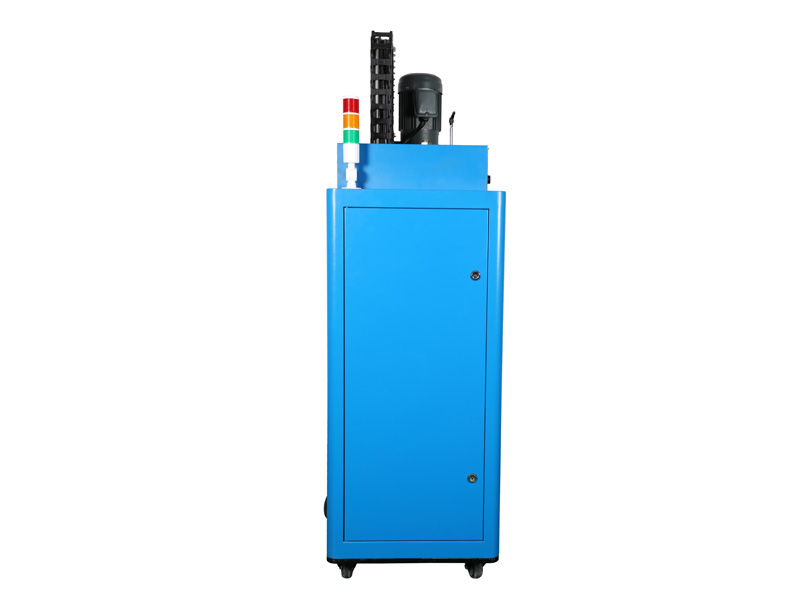

PUR 5s Gallon Hot Melt Glue Machine

hot melt glue equipmentGood sealing performance: There is an O - ring seal between the groove of the heating plate and the inner ring of the glue barrel, which can prevent the melted liquid colloid from contacting the air, solving the problem that PUR adhesives cannot contact the air during melting, and ensuring the performance of the glue.

hot melt glue equipment Easy to clean: The surface of the heating plate is coated with Teflon, which can prevent carbonization, reduce blockage, and is easy to clean. At the same time, the PTFE - coated fin platen is also easy to clean, which is conducive to maintaining the normal operation of the equipment.

- Saipu

- Dongguan, China

- 7-15 days

- more than 3000 sets per month

- Information

PUR 5 S Gallon Hot Melt Glue Machine

Equipped with a PLC intelligent touchscreen controller and PT100 Temperature sensors, it achieves ±1°C temperature accuracy within a range of 10–200°C.

A closed-loop feedback system adjusts heat output in real-time to compensate for ambient temperature fluctuations.

The pump design minimizes shear stress, preserving the adhesive’s chemical properties even at high viscosities.

Wide range of applications

(1) Woodworking wrapping and bonding

In the woodworking industry, it is used for the coating and bonding process of various types of boards, such as surface treatment of furniture door panels, decorative lines, etc. It can quickly and evenly apply hot melt adhesive, making decorative materials closely adhere to the board, improving the beauty and durability of the product.

(2) Textile Fabric Composite

Suitable for composite processing between textile fabrics, it firmly bonds different materials of fabrics together through hot melt adhesive, providing an efficient composite solution for the production of clothing, home textiles and other products, enhancing the functionality and added value of fabrics.

(3) PET transparent box

In the production process of PET transparent boxes, precise control of the adhesive amount is achieved to achieve a firm seal between the box body and the box cover, ensuring the integrity and aesthetics of product packaging, and meeting the high packaging requirements of industries such as food, cosmetics, and electronic products.

(4) Automotive interior parts, headlights

Provide reliable adhesive support for the assembly of automotive interior parts, such as the bonding of seats, instrument panels, and other components, as well as the sealing and assembly of car lights. High temperature resistant and high-strength hot melt adhesive can maintain stable performance in complex automotive environments, ensuring the quality and safety of automotive components.

(5) Book binding

In the field of book binding, fast and stable application of hot melt adhesive can achieve a strong bond between the pages and spine of the book, improve binding efficiency and book binding quality, and meet the production needs of large-scale book printing and binding.

(6) Assembly of household appliances

In the assembly process of household appliances, it is used for fixing and bonding components, such as the assembly of internal components of refrigerators, air conditioners, washing machines, etc. The good bonding performance of hot melt adhesive ensures the stability and reliability of electrical appliances during long-term use.

In summary, our 5-gallon hot melt adhesive machine, with its advanced technology, user-friendly design, and wide range of applications, has become a powerful assistant for various industries to improve production efficiency and ensure product quality. Choosing our hot melt adhesive machine means choosing an efficient, stable, and reliable production solution.

| System | Speed control AC motor gear pump |

| Barrel diameter | ¢280mm(286mm) |

| Maximum glue supply amount | 20kg/H |

| Output pipe | 1 line (or 2 lines) |

| Maximum working pressure | 8.5Mpa |

| Operating temperature scope | (RT)-250℃ |

| Environment temperature scope I | -20℃-50℃ |

| Temperature control precision | ±1℃ |

| Temperature sensor | Pt100 |

| Power supply | 220V |

| Maximum system power | 3.5KW |

| Air pressure applied | 0.5~0.8Mpa |

| Weight | 200kg |

| Connection signal | 2input,2output |

| Installation size | 1085mm*500mm*1450mm |

| Level of prevention | IP54 |

Our Factory

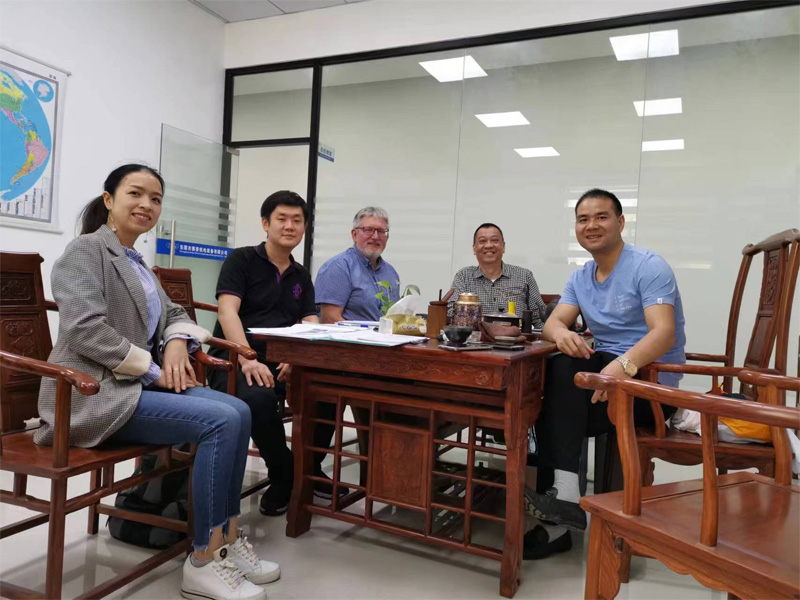

Saipu Electromechanical Device Co., Ltd. is a company that specializes in R&D, manufacturing, marketing and after-service of hot melt glue spraying machinery. Since the date of foundation, we have devoted ourselves to satisfy market demand by making products with better performance, more completed functions and higher quality. We have established a professional team that consists of experienced technical experts and managerial staffs, which help us to achieve development based on innovative and high technology.

1

Dongguan Saipu Electromechanical Device Co., Ltd.

2

Foshan Saipu Electromechanical Device Co., Ltd.

Our Team

Our enterprise spirit is: Pursuing for high-quality and perfection, providing sincere service to customers and brand-building based on the spirit of integrity". Our operation principle is "good reputation, honest business operation and making progress together". We will satisfy our customers' needs by providing them with high quality products and careful service, and create a bright future for them.

Our commitment to customer satisfaction does not end with the completion of the project. We provide comprehensive after-sales service, including maintenance, repair, and ongoing support. Our dedicated customer service team can address any questions or concerns that customers may have, ensuring their continued satisfaction with our products and services.

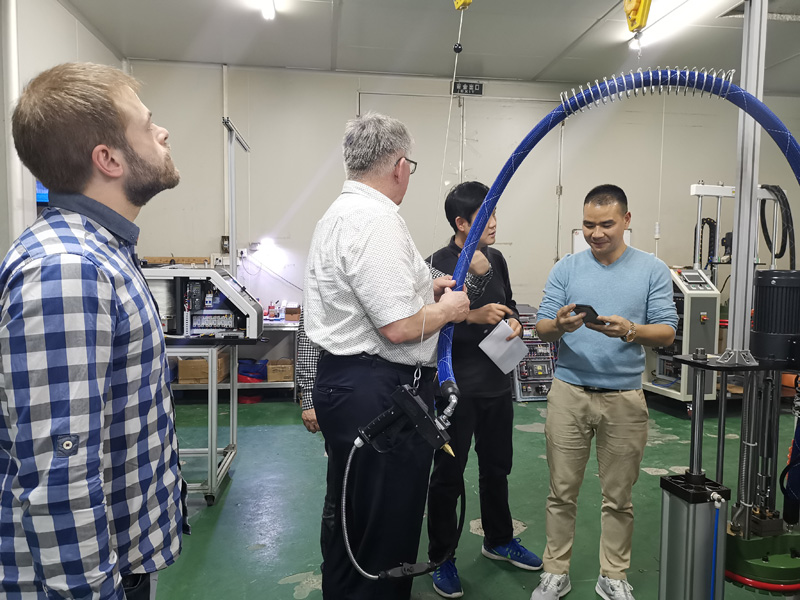

Our Exhibition

Dongguan Saipu Electromechanical Equipment Co., Ltd. is a company specializing in the research and development, manufacturing, sales, and after-sales service of hot melt adhesive spraying machinery. Saipu electromechanical equipment has participated in many national professional exhibitions, such as Russian Woodworking Machinery Exhibition, Türkiye Woodworking Machinery Exhibition, Hanover Woodworking Machinery Exhibition, Thailand Label Exhibition, etc. At the exhibition site, our hot melt adhesive machine attracted the attention of many customers with its excellent performance and reliable quality. From the completion of booth construction and the placement of product displays, a continuous stream of customers came to inquire. They raised questions about the operational efficiency, applicable scenarios, and ease of operation of the equipment, and our staff patiently answered them one by one, detailing the core advantages of the product.

Customer Visit

We adhere to our service objective: Credibility First and Customer First. We provide first-rate after-sales service to customers, and we make unremitting efforts to improve ourselves!

Application Scope

Our products are widely used in various sectors, including the packaging industry (carton box package, moon cake package, tea leaf box, cigarette case and beverage package), coating industry(acrylic foam tape, surgical gown, mask, mailing bags and hand bags), electronics industry(wires and cables), automobile industry(sealing materials for automobiles, car lamp manufacturing and windshield assembly), furniture industry(furniture gluing and laminating), hygienic products(disposable goods, e. g. Diapears and sanitary napkins), air filter industry, shoe-making industry, garment industry and book binding industry.

Assembly Diagram of Electrical Box

Our experienced professional team is responsible for the installation and construction of the hot melt adhesive machine. We follow industry best practices and safety standards, professional skills and knowledge to ensure a smooth and efficient installation process.

Logistics Packaging

Looking ahead to the future, Saipu Electromechanical will continue to focus on customer needs and continuously optimize our logistics system and service experience. Our mission is to help customers accelerate project development efficiently and safely - bringing Chinese made hot melt adhesive spraying machinery to farther places and making it stronger on the global stage.