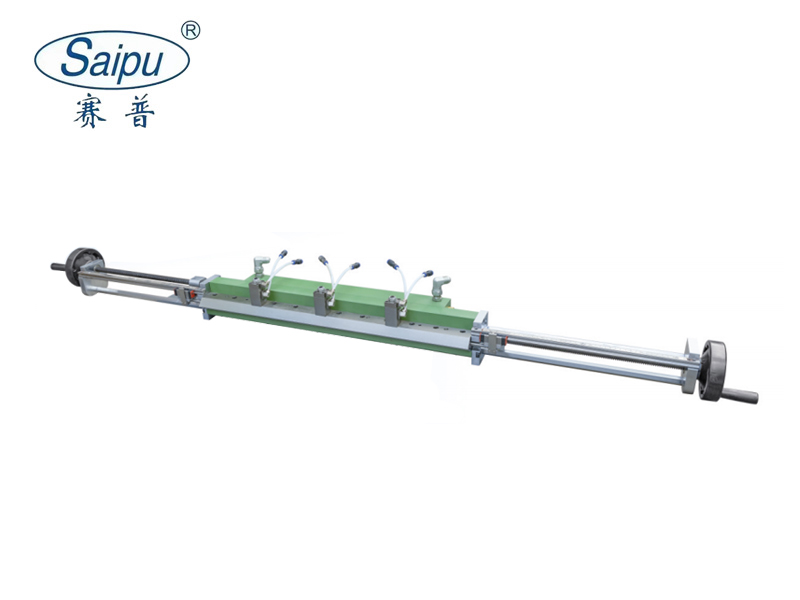

Hot Melt Glue Machine Accessories 650mm Scraper

Ultra wide and precise adhesive scraping: Scraper With a large size of 650mm, the adhesive scraping covers a wide area in one go, suitable for large format operations. The blade is finely ground to accurately control the thickness of the adhesive layer, with minimal deviation and even scraping to avoid adhesive accumulation and shortage, greatly improving production efficiency and product quality. It is suitable for large-scale adhesive coating scenarios in industries such as packaging and building materials.

High quality materials are durable and resistant to manufacturing: 650mm Scraper Imported high hardness special steel is used to create the blade, which has undergone special quenching treatment, resulting in high hardness and strong toughness.

- Saipu

- Dongguan, China

- 7-15 days

- more than 4000 sets per month

- Information

Hot Melt Glue Machine Accessories 650MM Scraper

Optimize Your Production Line with the Hot Melt Glue Machine 650mm Scraper

The Hot Melt Glue Machine 650mm Scraper is a highly efficient, industrial-grade tool designed to improve your production capabilities, particularly when working with edge bander machines and handbag gluing applications. This advanced machine uses hot melt adhesive to provide a smooth, precise bonding experience for a wide variety of materials, ensuring that your production lines operate at peak efficiency.

By combining a 650mm scraper with hot melt glue technology, this machine ensures consistent glue application that’s both fast and accurate. Its powerful scraper mechanism allows for a uniform spread of adhesive, reducing wastage and ensuring that every bond is secure. Whether you're working with woodworking, furniture manufacturing, or handbag production, the 650mm Scraper Hot Melt Glue Machine provides a seamless solution for your adhesive needs.

With the ability to control adhesive flow and temperature, this machine is a versatile and reliable tool that enhances production quality and reduces overall operational costs. Its application of hot melt glue offers faster drying times, making it ideal for high-demand environments where speed and precision are crucial.

650mm Scraper Hot Melt Glue Machine Versatile Applications for Edge Bander Machines

The 650mm Scraper Hot Melt Glue Machine is engineered to handle a variety of industrial applications, making it an indispensable tool for companies in different sectors. Its unique features allow it to work effectively across a range of materials and industries, including

Edge Bander Machines: When used with edge bander machines, the 650mm scraper ensures even adhesive application for edge banding in wood products. This is particularly useful for furniture manufacturers who need precise and uniform edge gluing to create aesthetically pleasing and durable products.

Packaging: This machine can also be used for packaging applications, ensuring that products are securely packed and bonded for transportation or retail purposes.

Electronics & Automotive: The hot melt glue is perfect for bonding delicate components in electronics manufacturing, as well as for automotive parts like sealing materials and trim.

This 650mm Scraper Hot Melt Glue Machine is ideal for industries where precision, durability, and efficiency are paramount, making it a versatile tool for any production line that involves glue bonding.

650mm Scraper Hot Melt Glue Machine Enhanced Efficiency and Precision in Every Application

One of the most significant advantages of the 650mm Scraper Hot Melt Glue Machine is its ability to enhance production efficiency while maintaining high precision. The hot melt adhesive ensures that bonds are made quickly and securely, with minimal waiting time for drying or curing. This means faster production cycles, allowing you to complete more orders in less time.

The scraper system provides an even spread of glue, reducing the need for excess adhesive and minimizing waste. By applying glue evenly across the surface, it helps maintain consistent product quality, whether you're working with wood, leather, fabric, or other materials. The precise application also reduces errors, ensuring that each piece adheres correctly on the first attempt, leading to cost savings and higher-quality finished products.

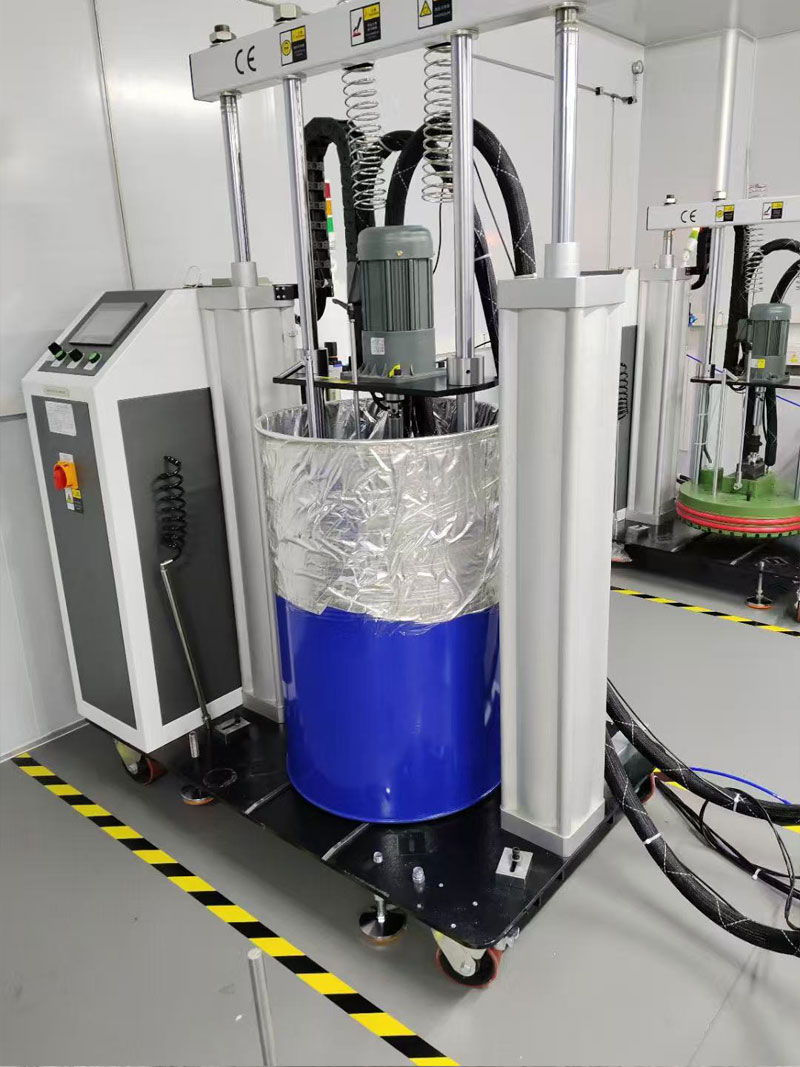

Our Factory

Saipu Electromechanical Device Co., Ltd. is a company that specializes in R&D, manufacturing, marketing and after-service of hot melt glue spraying machinery. Since the date of foundation, we have devoted ourselves to satisfy market demand by making products with better performance, more completed functions and higher quality. We have established a professional team that consists of experienced technical experts and managerial staffs, which help us to achieve development based on innovative and high technology.

1

Dongguan Saipu Electromechanical Device Co., Ltd.

2

Foshan Saipu Electromechanical Device Co., Ltd.

Our Team

Our enterprise spirit is: Pursuing for high-quality and perfection, providing sincere service to customers and brand-building based on the spirit of integrity". Our operation principle is "good reputation, honest business operation and making progress together". We will satisfy our customers' needs by providing them with high quality products and careful service, and create a bright future for them.

Our Exhibition

Over the years, Saipu Electromechanical Equipment has frequently appeared at renowned exhibitions worldwide: at the Russia Woodworking Machinery Exhibition, its hot melt adhesive spraying machines, specifically developed for

the woodworking industry, attracted significant attention from local woodworking enterprises due to their efficient spraying performance and adaptability. At the Turkey Woodworking Machinery Exhibition, the company's showcased

equipment, with its advanced technology and reliable performance, led to cooperative intentions with many Turkish companies. The Hannover Woodworking Machinery Exhibition in Germany, a top-tier event in the global

woodworking machinery sector, saw Saipu's products fully demonstrate the strength of "Intelligent Manufacturing in China," facilitating in-depth technical exchanges and collaborations with international peers. At the Thailand Label

Exhibition, the company's hot melt adhesive spraying solutions, tailored for the label industry, won widespread recognition from Southeast Asian clients by precisely meeting the special technical requirements of label production.

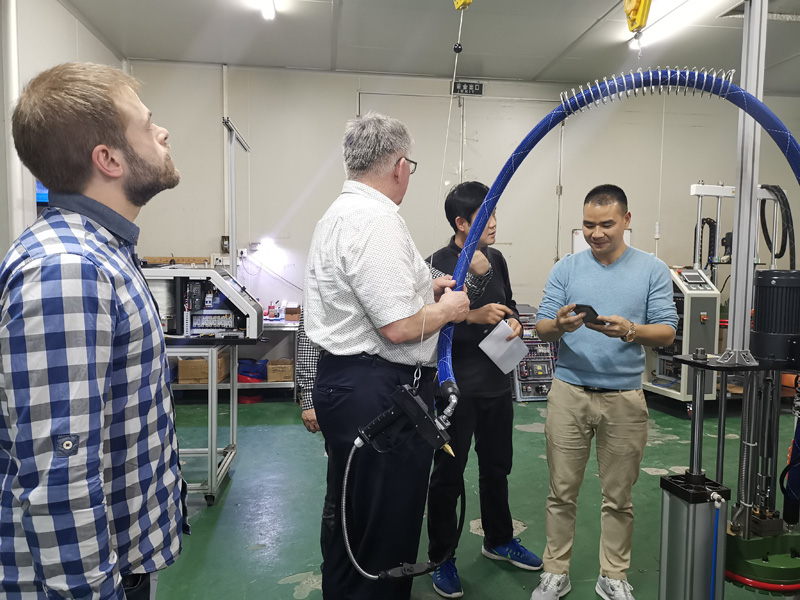

Customer Visit

As the saying goes, “it is more difficult to maintaining a existing customers tnandevelop new customers", So in our company, mostly of orders are from old customers,why is that? They know us, they know our products and trust us, they are at ease togive us order and trust us will complete the order well. They even recommend theirfriends to us,Hope you will be our next customers.

Application Scope

Our products are widely used in various sectors, including the packaging industry (carton box package, moon cake package, tea leaf box, cigarette case and beverage package), coating industry(acrylic foam tape, surgical gown, mask, mailing bags and hand bags), electronics industry(wires and cables), automobile industry(sealing materials for automobiles, car lamp manufacturing and windshield assembly), furniture industry(furniture gluing and laminating), hygienic products(disposable goods, e. g. Diapears and sanitary napkins), air filter industry, shoe-making industry, garment industry and book binding industry.

Assembly Diagram of Electrical Box

Our experienced professional team is responsible for the installation and construction of the hot melt adhesive machine. We follow industry best practices and safety standards, professional skills and knowledge to ensure a smooth and efficient installation process.

Logistics Packagin

Looking ahead to the future, Saipu Electromechanical will continue to focus on customer needs and continuously optimize our logistics system and service experience. Our mission is to help customers accelerate project development efficiently and safely - bringing Chinese made hot melt adhesive spraying machinery to farther places and making it stronger on the global stage.