Hot Melt Glue Machine Accessories 110mm Scraper

High wear-resistant material: Hot Melt Glue Machine Accessories 110mm Scraper is made of high-quality wear-resistant material and designed to withstand high temperatures, ensuring that it is not easily damaged after long-term use and extending its service life.

Accurate scraping: The hot melt adhesive machine accessory scraper with a width of 110mm provides uniform coating, reduces material waste, improves adhesive strength, and ensures perfect glue distribution.

Lightweight and easy to install: Hot Melt Glue Machine Accessories 110mm Scraper is designed with lightweight design, making it easy to operate. Users can quickly replace it without the need for professional tools, improving work efficiency.

- Saipu

- Dongguan, China

- 7-15 days

- more than 4000 sets per month

- Information

Hot Melt Glue Machine Accessories 110mm Scraper

High wear-resistant material: The 110mm scraper of the hot melt adhesive machine accessory is made of high-quality wear-resistant materials to ensure durability in high temperature environments and extend its service life.

Accurate scraping: The 110mm width design allows for even scraping of hot melt adhesive, ensuring even distribution of glue and improving bonding effectiveness.

Strong compatibility: Suitable for most hot melt glue machines on the market, easy to replace and upgrade, and improve equipment performance.

Lightweight design: Lightweight design allows for more flexible operation and reduces user fatigue during use.

Easy to clean: The surface is smooth and easy to clean after use, keeping the scraper clean and hygienic to avoid glue residue.

advantage

Improve work efficiency: Accurate scraping ability and fast heating response help users save time and improve efficiency in the production process.

Reduce material waste: Uniform glue application reduces excessive use and lowers material costs.

Improving adhesive strength: Good glue distribution can effectively enhance adhesive strength and ensure product quality.

Easy installation: The design is reasonable, and users can quickly replace the scraper without the need for professional tools, making it convenient and fast.

110mm scraper Installation steps:

Turn off the power of the hot melt adhesive machine and wait for the equipment to cool down.

Disassemble the old scraper and clean the installation position.

Align the new scraper with the installation hole and ensure that it is firmly fixed after alignment.

110mm scraper Operation process:

Turn on the power of the hot melt adhesive machine and preheat it to the set temperature.

Apply hot melt adhesive evenly to the desired surface, ensuring that the scraper maintains appropriate pressure on the surface.

After use, turn off the power and clean the device after it has cooled down.

110mm Scraper Precautions

Temperature control: During use, please ensure that the temperature of the hot melt adhesive machine remains within a safe range to avoid overheating and damage to the scraper.

Regular inspection: It is recommended to regularly check the wear of the scraper and replace it in a timely manner to maintain optimal performance.

Avoid collision: When using, avoid collisions between the scraper and hard objects to prevent damage or deformation of the scraper.

Storage method: When not in use, please store the scraper in a dry, cool place, away from direct sunlight and humid environment.

Through the above information, you can better understand and use the 110mm hot melt adhesive machine accessory scraper, improve your work efficiency, and ensure product quality.

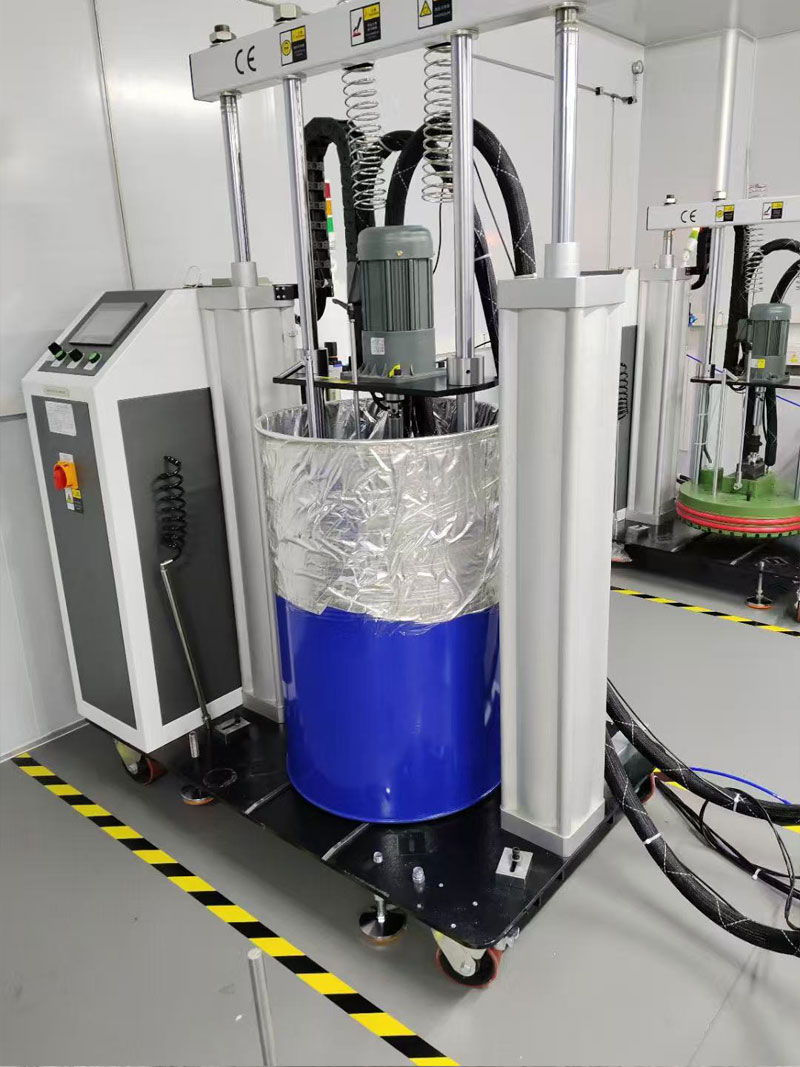

Our Factory

Saipu Electromechanical Device Co., Ltd. is a company that specializes in R&D, manufacturing, marketing and after-service of hot melt glue spraying machinery. Since the date of foundation, we have devoted ourselves to satisfy market demand by making products with better performance, more completed functions and higher quality. We have established a professional team that consists of experienced technical experts and managerial staffs, which help us to achieve development based on innovative and high technology.

1

Dongguan Saipu Electromechanical Device Co., Ltd.

2

Foshan Saipu Electromechanical Device Co., Ltd.

Our Team

Our enterprise spirit is: Pursuing for high-quality and perfection, providing sincere service to customers and brand-building based on the spirit of integrity". Our operation principle is "good reputation, honest business operation and making progress together". We will satisfy our customers' needs by providing them with high quality products and careful service, and create a bright future for them.

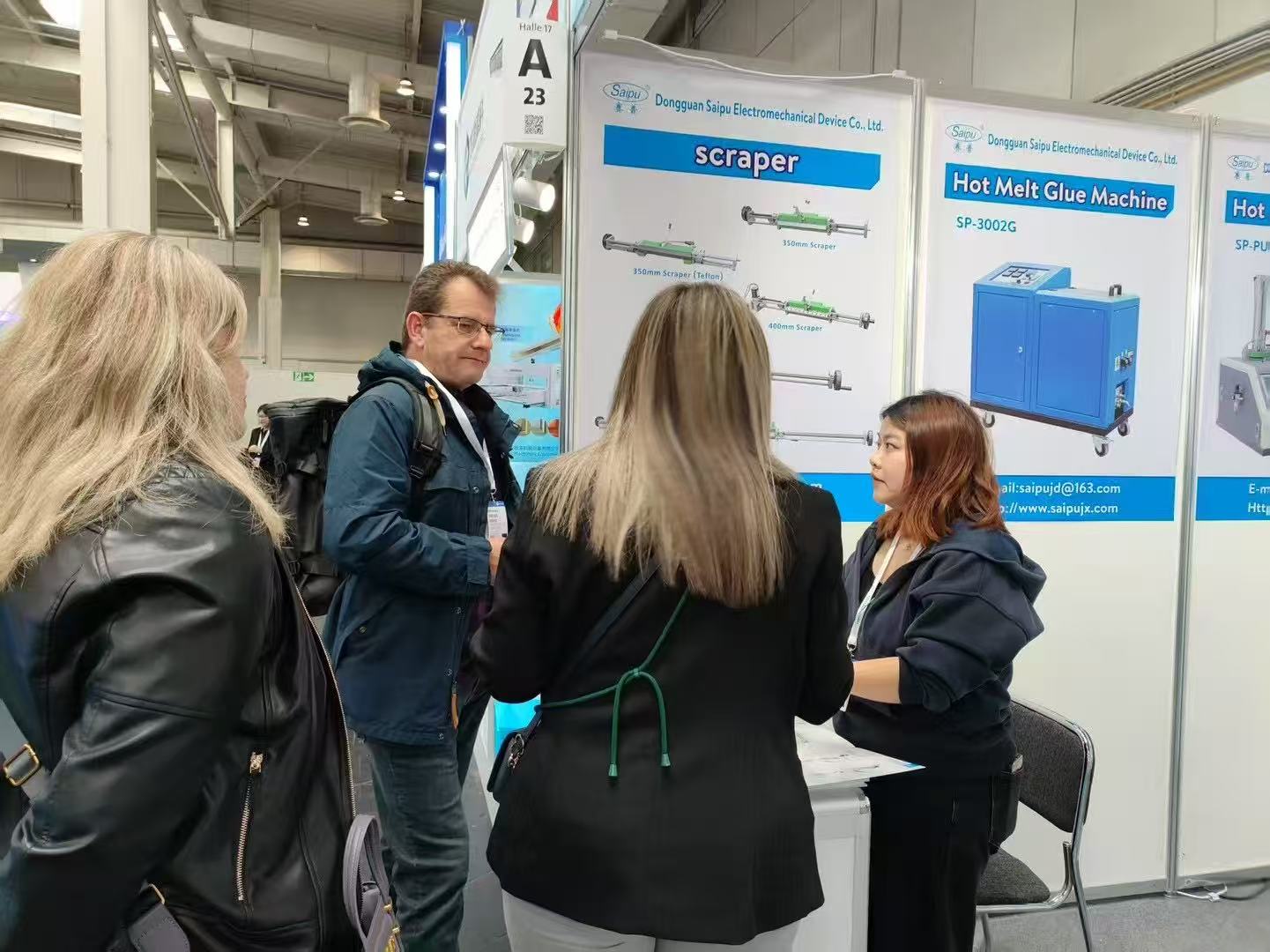

Our Exhibition

Dongguan Saipu Electromechanical Equipment Co., Ltd. is a company specializing in the research and development, manufacturing, sales, and after-sales service of hot melt adhesive spraying machinery. Saipu electromechanical equipment has participated in many national professional exhibitions, such as Russian Woodworking Machinery Exhibition, Türkiye Woodworking Machinery Exhibition, Hanover Woodworking Machinery Exhibition, Thailand Label Exhibition, etc. At the exhibition site, our hot melt adhesive machine attracted the attention of many customers with its excellent performance and reliable quality. From the completion of booth construction and the placement of product displays, a continuous stream of customers came to inquire. They raised questions about the operational efficiency, applicable scenarios, and ease of operation of the equipment, and our staff patiently answered them one by one, detailing the core advantages of the product.

It is gratifying that many customers have shown strong interest in our hot melt adhesive machine after in-depth understanding, and have actively added their contact information, hoping to further communicate the details of cooperation in the future. What is even more encouraging for us is that some customers confirmed their intention to cooperate on site and directly placed orders, which makes us cherish this trust.

Through this exhibition, we not only showcased the strength of our products, but also established close connections with customers from all over the world. This is not only a recognition of our products, but also a driving force for us to continuously improve quality and optimize services in the future. We look forward to working together with these new customers and welcome more partners with needs to contact us to create a better future for cooperation.

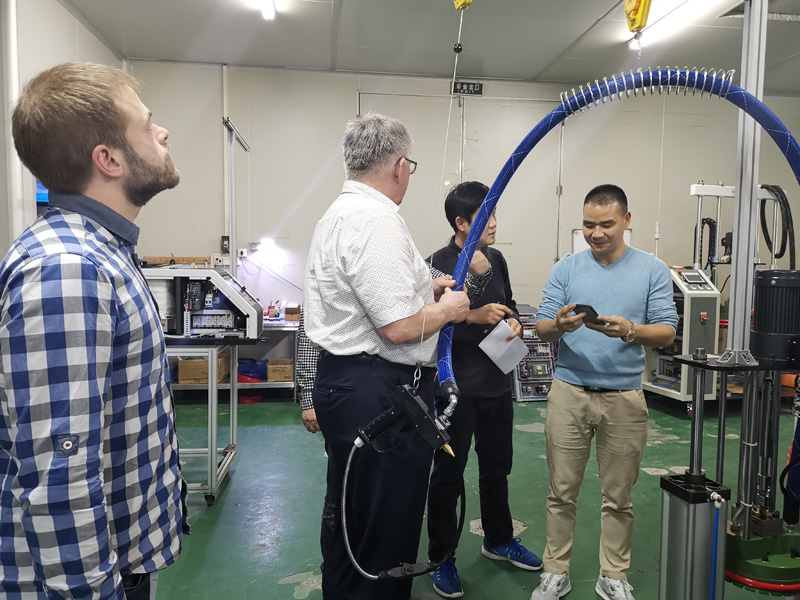

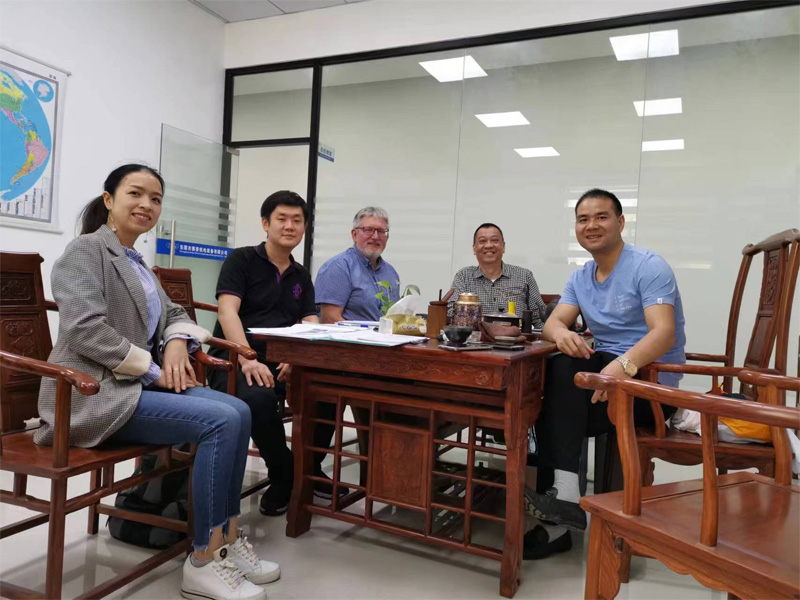

Customer Visit

As the saying goes, “it is more difficult to maintaining a existing customers tnandevelop new customers", So in our company, mostly of orders are from old customers,why is that? They know us, they know our products and trust us, they are at ease togive us order and trust us will complete the order well. They even recommend theirfriends to us,Hope you will be our next customers.

Application Scope

Our products are widely used in various sectors, including the packaging industry (carton box package, moon cake package, tea leaf box, cigarette case and beverage package), coating industry(acrylic foam tape, surgical gown, mask, mailing bags and hand bags), electronics industry(wires and cables), automobile industry(sealing materials for automobiles, car lamp manufacturing and windshield assembly), furniture industry(furniture gluing and laminating), hygienic products(disposable goods, e. g. Diapears and sanitary napkins), air filter industry, shoe-making industry, garment industry and book binding industry.

Assembly Diagram of Electrical Box

Our experienced professional team is responsible for the installation and construction of the hot melt adhesive machine. We follow industry best practices and safety standards, professional skills and knowledge to ensure a smooth and efficient installation process.

Logistics Packaging

Looking ahead to the future, Saipu Electromechanical will continue to focus on customer needs and continuously optimize our logistics system and service experience. Our mission is to help customers accelerate project development efficiently and safely - bringing Chinese made hot melt adhesive spraying machinery to farther places and making it stronger on the global stage.