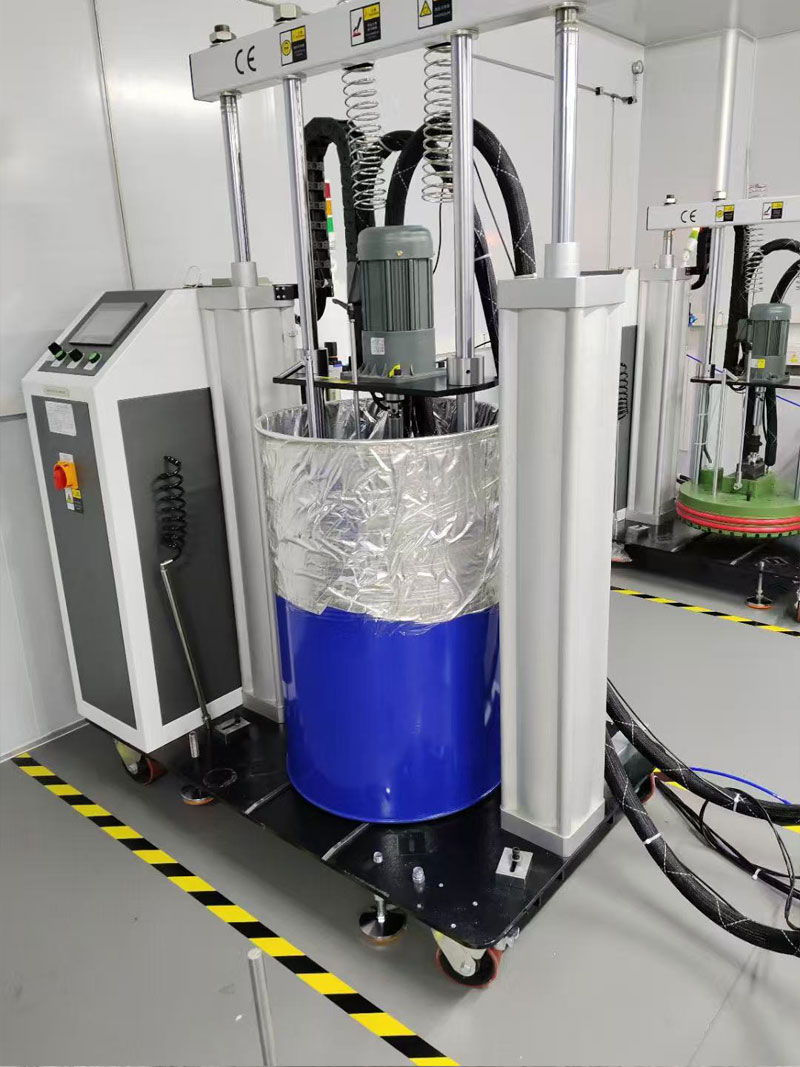

500 Liters Hot Melt Glue Machine

✔ Extra-Large Capacity – 500-liter tank minimizes frequent refilling, boosting productivity in high-demand environments.

✔ Rapid & Uniform Melting – High-power heating system ensures fast melting of hot melt adhesives with no cold spots.

✔ Precision Temperature Control – Digital PID thermostat (±1°C accuracy) maintains optimal viscosity for smooth application.

✔ High-Performance Pump System – Choice of heavy-duty gear pump or pneumatic pump for consistent, adjustable glue output

✔ Energy-Efficient Design – Insulated tank reduces heat loss, lowering power consumption.

✔ Customizable Configurations – Optional PLC control, automated dispensing systems, insulated hoses, and multi-nozzle setups.

- Saipu

- Dongguan, China

- 7-15 days

- more than 3000 sets per month

- Information

500 Liters Hot Melt Glue Machine

500 liter hot melt adhesive machine: the core driving force for industrial grade large-scale bonding

As a super large capacity industrial bonding equipment, the 500 liter hot melt adhesive machine has become an indispensable core equipment in large-scale production scenarios due to its strong continuous adhesive supply capacity, efficient and stable performance, and wide industry adaptability. From packaging and woodworking to automotive, electronics, textile and other fields, it has solved large-scale and high demand bonding problems for various industries with multiple advantages of "high-strength bonding+efficient production+environmental protection and safety", becoming a key driving force for promoting production upgrading.

Core advantage of ultra large capacity: supporting large-scale continuous production

The 500 liter ultra large melt adhesive tank design is the "hardcore strength" of this equipment, tailor-made for large-scale production lines with an average daily production capacity of tens or even hundreds of thousands of pieces. Compared to the pain points of frequent shutdown and feeding of small and medium-sized equipment, the 500 liter hot melt adhesive machine can store a large amount of solid adhesive material at once. With the intelligent material level monitoring system, it can achieve long-term continuous adhesive supply, greatly reducing production interruptions caused by feeding. Whether it is the high-speed cardboard box sealing line in the food and beverage industry, the batch assembly line in furniture factories, or the large-scale production workshop of automotive parts, it can stably output adhesive volume, ensure that the production rhythm is not disconnected, and fundamentally improve the continuity and efficiency of large-scale production.

Efficient heating and precise temperature control: ensuring bonding quality and stability

Large scale production requires extremely high consistency in bonding, and the 500 liter hot melt adhesive machine achieves precise control of the bonding process through advanced technology. The equipment is equipped with a multi zone uniform heating system, which can quickly melt solid adhesive into a temperature stable liquid adhesive. The temperature fluctuation during the adhesive process can be controlled within ± 2 ℃, avoiding local overheating that may cause aging of the adhesive, decrease in viscosity, or insufficient bonding strength due to insufficient temperature. At the same time, it is equipped with an intelligent temperature control module to ensure optimal adhesion when bonding different materials such as plastic, wood, metal, and fabric. This ability of "stable temperature control+adaptability adjustment" enables every product in large-scale production to maintain consistent adhesive quality.

For more information or to inquire about our 500 Liters Hot Melt Glue Machine, please contact us. We are committed to providing innovative solutions that meet the evolving needs of our customers in adhesive technology.

| Model | SP-50002G(500 Liters) |

| Voltage | 380V |

| Frequencyi | 50HZ |

| Power | 68 KW |

| Hopper Capacity | 500Kg |

| Melt rate | 520Kg |

| Range of Temperature | ≤260℃ |

| Up to hose's nummber | 1 lime (or 4lines) |

| Overall Size | 1700x1150x1780(mm) |

| Weight | 800Kg |

Our Factory

Saipu Electromechanical Device Co., Ltd. is a company that specializes in R&D, manufacturing, marketing and after-service of hot melt glue spraying machinery. Since the date of foundation, we have devoted ourselves to satisfy market demand by making products with better performance, more completed functions and higher quality. We have established a professional team that consists of experienced technical experts and managerial staffs, which help us to achieve development based on innovative and high technology.

1

Dongguan Saipu Electromechanical Device Co., Ltd.

2

Foshan Saipu Electromechanical Device Co., Ltd.

Our Team

Our enterprise spirit is: Pursuing for high-quality and perfection, providing sincere service to customers and brand-building based on the spirit of integrity". Our operation principle is "good reputation, honest business operation and making progress together". We will satisfy our customers' needs by providing them with high quality products and careful service, and create a bright future for them.

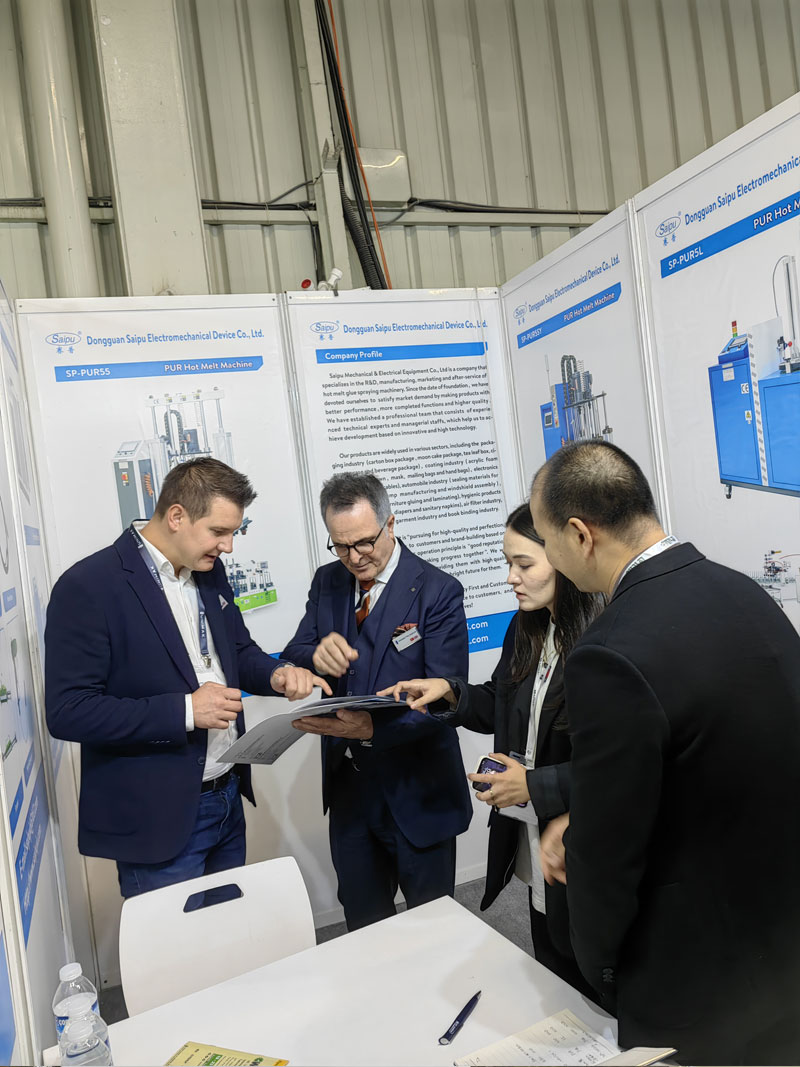

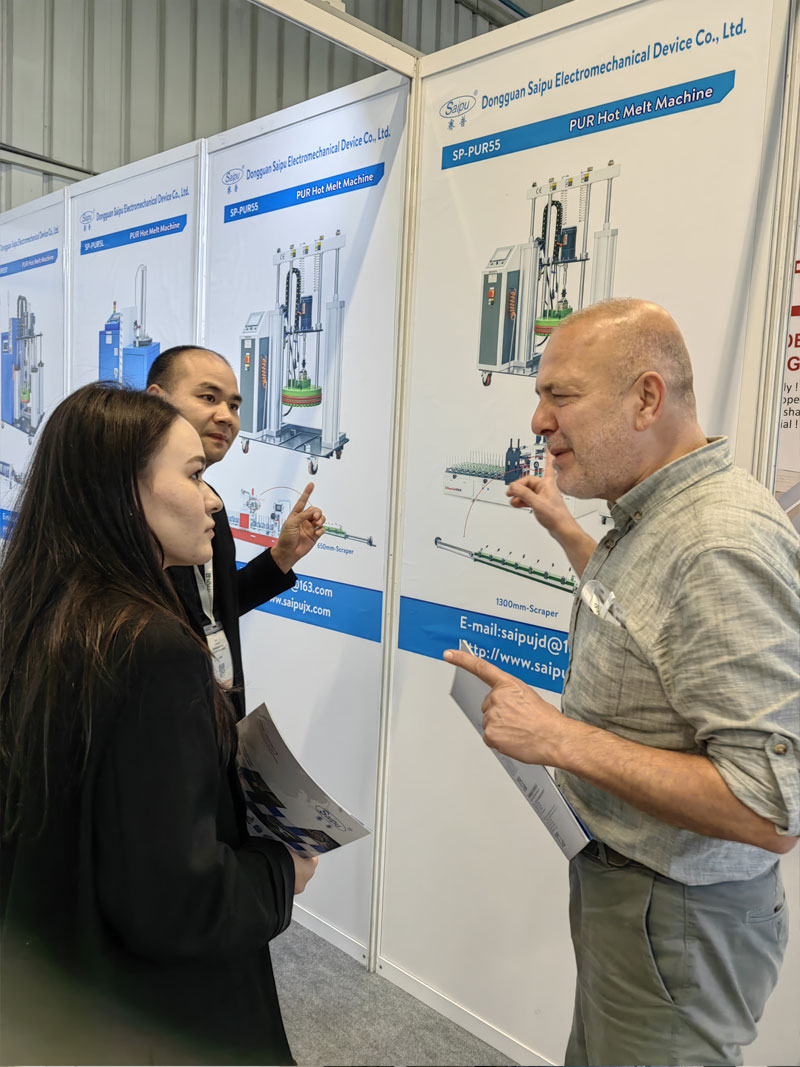

Our Exhibition

Over the years, Saipu Electromechanical Equipment has frequently appeared at renowned exhibitions worldwide: at the Russia Woodworking Machinery Exhibition, its hot melt adhesive spraying machines, specifically developed for the woodworking industry, attracted significant attention from local woodworking enterprises due to their efficient spraying performance and adaptability. At the Turkey Woodworking Machinery Exhibition, the company's showcased equipment, with its advanced technology and reliable performance, led to cooperative intentions with many Turkish companies. The Hannover Woodworking Machinery Exhibition in Germany, a top-tier event in the global woodworking machinery sector, saw Saipu's products fully demonstrate the strength of "Intelligent Manufacturing in China," facilitating in-depth technical exchanges and collaborations with international peers. At the Thailand Label Exhibition, the company's hot melt adhesive spraying solutions, tailored for the label industry, won widespread recognition from Southeast Asian clients by precisely meeting the special technical requirements of label production.

Customer Visit

We adhere to our service objective: Credibility First and Customer First. We provide first-rate after-sales service to customers, and we make unremitting efforts to improve ourselves!

Application Scope

Our commitment to customer satisfaction does not end with the completion of the project. We provide comprehensive after-sales service, including maintenance, repair, and ongoing support. Our dedicated customer service team can address any questions or concerns that customers may have, ensuring their continued satisfaction with our products and services

Assembly Diagram of Electrical Box

Our experienced professional team is responsible for the installation and construction of the hot melt adhesive machine. We follow industry best practices and safety standards, professional skills and knowledge to ensure a smooth and efficient installation process.

Logistics Packaging

Looking ahead to the future, Saipu Electromechanical will continue to focus on customer needs and continuously optimize our logistics system and service experience. Our mission is to help customers accelerate project development efficiently and safely - bringing Chinese made hot melt adhesive spraying machinery to farther places and making it stronger on the global stage.