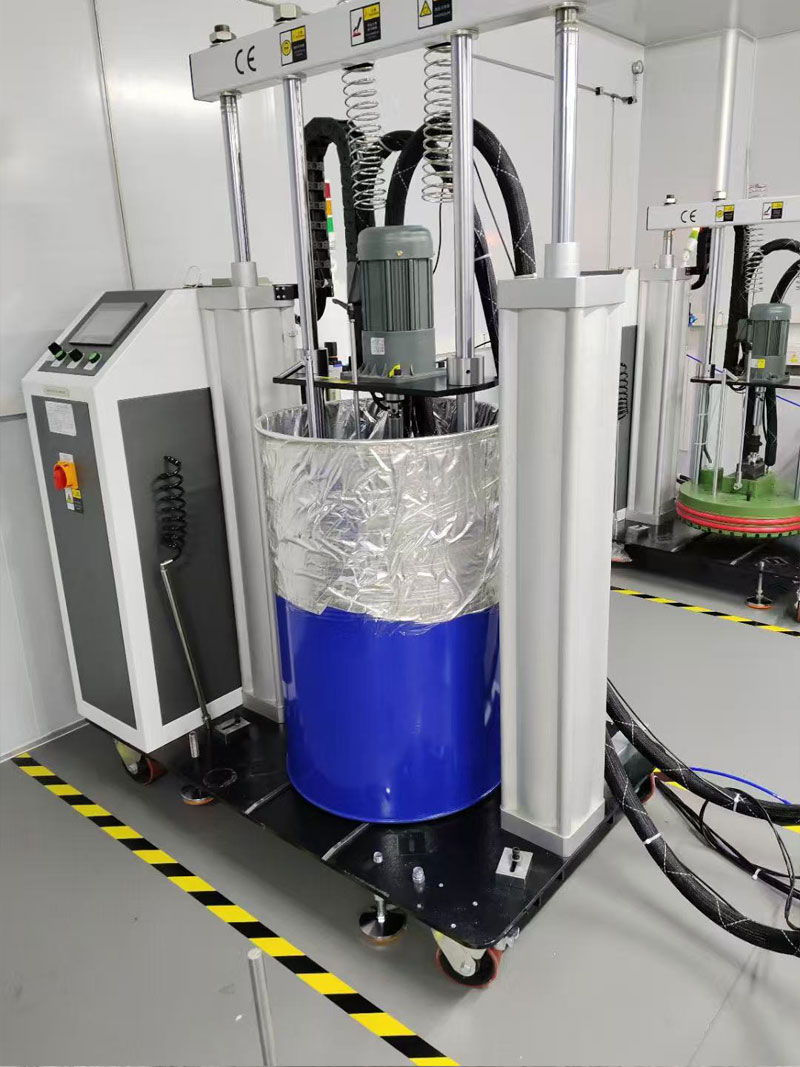

200 Liters Hot Melt Glue Machine

✔ Large Capacity – 200-liter tank for bulk adhesive storage, reducing frequent refills.

✔ Fast & Uniform Melting – Advanced heating system ensures quick and even melting of hot melt adhesives

✔ Precise Temperature Control – Digital thermostat (±1°C accuracy) for optimal viscosity and performance.

✔ High-Efficiency Pump – Gear pump or pneumatic pump options for consistent glue delivery

✔ Safety Features – Overheat protection, insulation

✔ Customizable Options – Available with hose, nozzle, or automatic dispensing systems.

- Saipu

- Dongguan, China

- 7-15 days

- more than 3000 sets per month

- Information

Product Description of 200 Liters Hot Melt Glue Machine

200 Liters Hot Melt Glue Machine Glue dispensing speed: supporting high production capacity demand with large capacity and efficient power

1. High flow gear pump+fully open control valve to improve adhesive supply efficiency

The equipment is equipped with a customized high flow gear pump, which is designed with precision teeth and processed with high sealing performance. The single batch glue output far exceeds that of small equipment, and can meet the needs of wide range glue application (such as furniture board bonding, large packaging edge sealing) or high-frequency glue application (such as fixing automotive interior components). The unobstructed passage design with a fully open flow control valve minimizes the flow resistance of the rubber material, fully unleashes the power of the gear pump, and improves the rubber material conveying efficiency by more than 15% compared to traditional equipment.

2. Efficient melt adhesive system ensures the speed of adhesive supply from the source

The combination of high-strength integrated melt adhesive tank and distributed radiation heating plate significantly improves the melting efficiency of 200 liters of large capacity adhesive material, avoiding "glue supply interruption" caused by insufficient melt adhesive speed. Whether it is the preheating of the refrigeration machine or the rapid heating after filling the glue in the middle, the glue material can be melted into a uniform liquid state in a short time, ensuring that the gear pump continues to suck glue and output stably, eliminating the hidden danger of "glue speed fluctuation" from the source.

200 Liters Hot Melt Glue Machine Adhesive stability: from temperature control to structural design, eliminating fluctuations and defects

1. Precise temperature control+anti carbonization design to ensure stable adhesive properties of the adhesive material

The core premise of adhesive stability is the uniform state of the adhesive material. The equipment achieves precise temperature control within ± 1 ℃ through a touch screen intelligent temperature control system, combined with the uniform heat transfer of the radiation heating element, to ensure that the temperature of the entire 200 liter adhesive material is consistent, avoiding carbonization of the adhesive material caused by local overheating or impurities in the adhesive particles caused by local melting. The stable state of the adhesive material provides a basic guarantee for uniform dispensing, eliminating the problem of "dispensing quickly and slowly" caused by fluctuations in adhesive viscosity.

2. Precise structure of gear pump+independent suspension system, reducing mechanical fluctuations

Precision gear pump: Through high-precision tooth meshing and sealing design, it ensures that the glue output error of each rotation is controlled within ± 2%, completely eliminating the phenomenon of "pulse glue output" or "glue breakage". Even if it runs continuously for a long time, the glue output can remain stable;

External independent suspension system: Flexibly separate the gear pump from the glue tank to reduce the impact of vibration transmission on the gear pump during equipment operation, while avoiding mechanical wear caused by direct heat transfer from the glue tank to the pump body, further extending the stable operating life of the gear pump.

| Model | SP-20002G |

| Voltage | 380V |

| Frequency | 50Hz |

| Power | 30KW |

| Hopper capacity | 200Kg |

| Melt rate | 120Kg |

| Range of temperature | ≤230℃ |

| Up to hose's number | 1 line (or 4lines) |

| Overall size | (L)1420x(W)850x(H)1222mm |

| Weight | 400Kg |

Our Factory

Saipu Electromechanical Device Co., Ltd. is a company that specializes in R&D, manufacturing, marketing and after-service of hot melt glue spraying machinery. Since the date of foundation, we have devoted ourselves to satisfy market demand by making products with better performance, more completed functions and higher quality. We have established a professional team that consists of experienced technical experts and managerial staffs, which help us to achieve development based on innovative and high technology.

1

Dongguan Saipu Electromechanical Device Co., Ltd.

2

Foshan Saipu Electromechanical Device Co., Ltd.

Our Team

Our enterprise spirit is: Pursuing for high-quality and perfection, providing sincere service to customers and brand-building based on the spirit of integrity". Our operation principle is "good reputation, honest business operation and making progress together". We will satisfy our customers' needs by providing them with high quality products and careful service, and create a bright future for them.

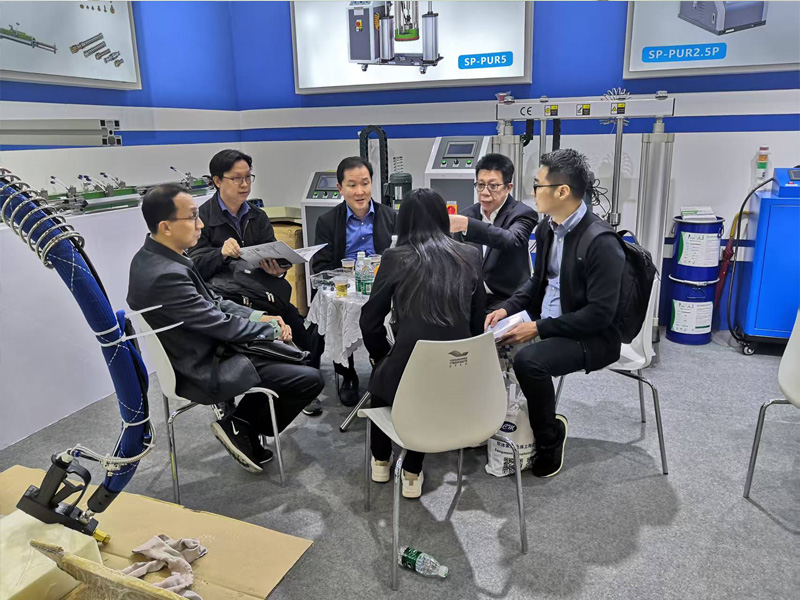

Our Exhibition

Dongguan Saipu Electromechanical Equipment Co., Ltd. is a company specializing in the research and development, manufacturing, sales, and after-sales service of hot melt adhesive spraying machinery. Saipu electromechanical equipment has participated in many national professional exhibitions, such as Russian Woodworking Machinery Exhibition, Türkiye Woodworking Machinery Exhibition, Hanover Woodworking Machinery Exhibition, Thailand Label Exhibition, etc. At the exhibition site, our hot melt adhesive machine attracted the attention of many customers with its excellent performance and reliable quality. From the completion of booth construction and the placement of product displays, a continuous stream of customers came to inquire. They raised questions about the operational efficiency, applicable scenarios, and ease of operation of the equipment, and our staff patiently answered them one by one, detailing the core advantages of the product.

Customer Visit

We adhere to our service objective: Credibility First and Customer First. We provide first-rate after-sales service to customers, and we make unremitting efforts to improve ourselves!

Application Scope

Our products are widely used in various sectors, including the packaging industry (carton box package, moon cake package, tea leaf box, cigarette case and beverage package), coating industry(acrylic foam tape, surgical gown, mask, mailing bags and hand bags), electronics industry(wires and cables), automobile industry(sealing materials for automobiles, car lamp manufacturing and windshield assembly), furniture industry(furniture gluing and laminating), hygienic products(disposable goods, e. g. Diapears and sanitary napkins), air filter industry, shoe-making industry, garment industry and book binding industry.

Our commitment to customer satisfaction does not end with the completion of the project. We provide comprehensive after-sales service, including maintenance, repair, and ongoing support. Our dedicated customer service team can address any questions or concerns that customers may have, ensuring their continued satisfaction with our products and services

Assembly Diagram of Electrical Box

Our experienced professional team is responsible for the installation and construction of the hot melt adhesive machine. We follow industry best practices and safety standards, professional skills and knowledge to ensure a smooth and efficient installation process.

Logistics Packaging

Looking ahead to the future, Saipu Electromechanical will continue to focus on customer needs and continuously optimize our logistics system and service experience. Our mission is to help customers accelerate project development efficiently and safely - bringing Chinese made hot melt adhesive spraying machinery to farther places and making it stronger on the global stage.