How Hot Melt Adhesive Machines Transform Automotive Manufacturing: Precision Bonding for Modern Vehicles

2025-12-02 10:46From the bonding of headlights to the sealing of windshields, from seat assembly to trunk insulation, automotive factories today rely more than ever on stable, clean, and efficient adhesive systems. Mechanical fastening is no longer enough for lightweight structures and multi-material designs. Instead, thermal bonding technologies have quietly become the backbone of modern car manufacturing—and at the heart of that shift stands the Hot Melt Glue Machine, the Hot Melt Glue Equipment,and the high-precision Hot Melt Adhesive Machine.

Dongguan Saipu Electromechanical Device Co., Ltd., a specialist in advanced hot melt adhesive systems, has spent years supporting automotive OEMs and Tier-1 suppliers across sealing materials, headlamp bonding, interior assembly, and windshield structural lines. In each application, consistency is everything—and consistent results begin with understanding how the adhesive behaves when heated.

■ Why Hot Melt Adhesives Matter in Automobiles

The automotive industry demands bonding solutions that are:

Strong but flexible enough to handle vibration

Heat-resistant through engine bay and summer temperatures

Clean, without residues that affect electronics

Fast-curing to match high-speed assembly lines

This is why manufacturers depend on high-performance dispensing systems like the Hot Melt Glue Machine, engineered for stable flow and clean application. Whether it’s laminating interior panels or assembling lighting housings, each layer of adhesive must perform flawlessly.

But what happens when bubbles appear in the adhesive after melting?

The answer: bonding failure, product defects, and ultimately higher production costs.

■ The Bubble Challenge — A Hidden Threat in Automotive Bonding

In automotive manufacturing, even a tiny bubble inside a glue bead can cause:

Headlamp leakage

Windshield sealing failure

Door panel delamination

Seat fabric lifting

Trunk trim detachment

These issues often arise from the same root causes. Regardless of whether the line uses a Hot Melt Glue Machine, Hot Melt Glue Equipment, or a Hot Melt Adhesive Machine, the problem follows predictable patterns.

■ Three Major Causes of Bubbles After the Adhesive Melts

1. Moisture in the Adhesive

When the adhesive absorbs moisture, the high-temperature melt turns it into steam. Because the molten adhesive is thick, vapor becomes trapped inside, creating bubbles that weaken automotive bonding lines.

This affects every system:

Pellet adhesives for the Hot Melt Adhesive Machine

Blocks used in Hot Melt Glue Equipment

Sticks loaded into a smaller Hot Melt Glue Machine

2. Chemical Cross-Reactions

Mixing adhesives from different suppliers—common in multi-line automotive plants—can trigger chemical reactions that release gas during melting. Even tiny residue levels can cause cross-talk.

3. Air Entering the Delivery Port

When a glue tank is filled below its minimum level, both air and glue enter the pump. This produces air-filled glue beads that appear normal but bond with reduced strength.

This issue is especially common in oversized Hot Melt Glue Equipment running low-volume processes.

■ How to Solve Bubble Problems in Automotive Glue Lines

A. Address Moisture

Dry adhesives before loading

Keep tanks sealed when idle

Store blocks and pellets in low-humidity areas

Stable melting ensures automotive-grade bonding performance.

B. Avoid Cross-Material Reactions

Clean tanks when changing brands

Standardize adhesive types across production shifts

Flush older material before switching formulations

C. Maintain Proper Tank Levels

Follow minimum fill standards

Use sized-correct Hot Melt Glue Machine models

Avoid running tanks nearly empty to “save material”

These steps ensure that when the adhesive melts, it flows smoothly—even in fast-paced automotive environments.

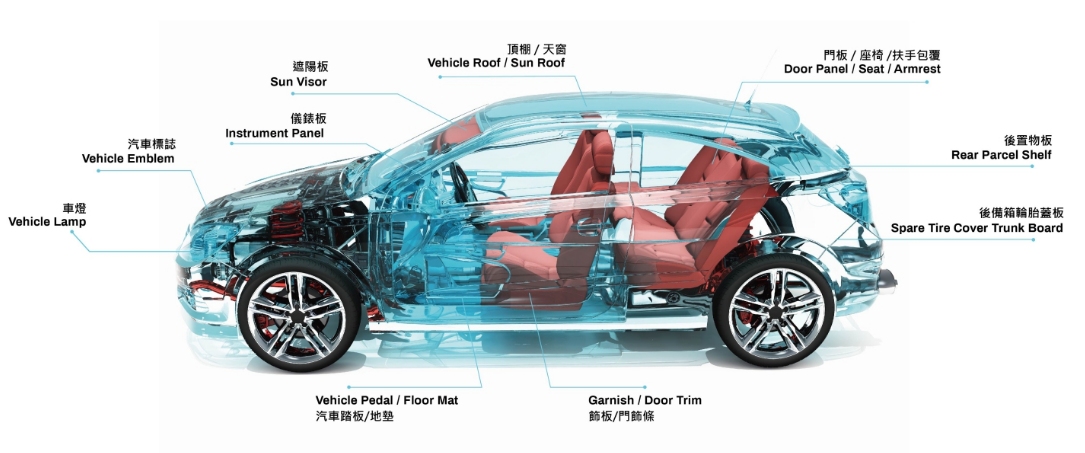

■ Where Hot Melt Adhesive Machines Are Used in Automobiles

1. Windshield and Window Assembly

A Hot Melt Adhesive Machine delivers precise beads for sealing glass to body frames, ensuring durability, noise reduction, and waterproof performance.

2. Headlamp Manufacturing

Consistent glue lines prevent fogging, moisture leaks, and separation—especially critical as lighting systems integrate electronics.

3. Interior Trim and Seat Assembly

A Hot Melt Glue Machine applies clean, uniform adhesive for fabric lamination, foam bonding, leather wrapping, and panel attachment.

4. Trunk and Door Panel Bonding

Hot melt systems help bond insulation layers, plastic trims, fiber mats, and sound-deadening materials.

5. Wire Harness Fixing and Electronic Adhesion

Precise Hot Melt Glue Equipment ensures clean cable fixation and protects electronic modules from vibration.

6. NVH (Noise, Vibration, Harshness) Materials

Automotive acoustic foams and sound insulation pads rely heavily on stable, bubble-free adhesive distribution.

■ Industry Analysis Table: Hot Melt Application in Automotive Production

| Application Segment | Value for Automakers | Risks Without Proper Equipment | Benefits of Saipu Hot Melt Systems |

| Windshields | Strong sealing, structural support | Leaks, detachment | Stable bead flow, strong bonding |

| Headlamps | Water-tight housing | Fogging, cracking | Uniform glue lines |

| Seats & Trim | Comfort and aesthetics | Wrinkles, delamination | Clean lamination |

| Door Panels | Noise reduction | Loose interiors | High-precision coating |

| Electronics | Vibration protection | Module failure | Controlled micro-dispensing |

| Trunk Panels | Structural bonding | Rattling, gaps | Strong, even coverage |

With the right Hot Melt Glue Equipment, automakers reduce scrap rates, improve assembly consistency, and enhance long-term safety.

■ FAQ

Q1: Why do bubbles cause bonding failure in cars?

Because bubbles interrupt surface contact, weakening structural adhesion—especially critical in windshields and lights.

Q2: Can all adhesives be used with any Hot Melt Glue Machine?

Not recommended. Automotive adhesives differ by resin type, temperature, viscosity, and reaction behavior.

Q3: How often should we clean the glue tank?

Whenever switching brands or formulations. For high-precision lines, weekly cleaning is standard.

Q4: Does the Hot Melt Adhesive Machine require regular calibration?

Yes. Device pressure, temperature curves, and nozzle condition all affect bonding uniformity.

■ Call to Action

Dongguan Saipu offers professional support for automotive manufacturers:

✔ Full-line integration for Hot Melt Glue Machine and Hot Melt Glue Equipment systems

✔ Application testing for windshield, headlamp, interior, and trunk bonding

✔ Free “Automotive Hot Melt Inspection Checklist.”

✔ Expert troubleshooting for bubble formation

You can contact us to schedule a free consultation or request technical guidance.

Conclusion

From exterior sealing to interior comfort, hot melt adhesive technology shapes the reliability, safety, and quality of modern vehicles.

Whether applied through a Hot Melt Glue Machine, complex Hot Melt Glue Equipment, or a precision-controlled Hot Melt Adhesive Machine, stability and bubble-free melting define the success of every automotive bonding point.

As vehicles evolve toward lightweight materials, EV platforms, and smart interiors, adhesive systems become even more important—and companies like Dongguan Saipu ensure that manufacturers stay ready for the next generation of automotive innovation.