Hot Melt Adhesive Machine Application in the Household Appliances industry

2025-12-17 10:40In the household appliances industry, performance is measured not only by functionality, but by durability, energy efficiency, and long-term safety. From refrigerator insulation to electronic module assembly, bonding technology plays a critical role behind the scenes. Today, the Hot Melt Adhesive Machine has become a key manufacturing solution across appliance production lines, supporting stable foaming, precise sealing, and clean electrical assembly.

Dongguan Saipu Electromechanical Device Co., Ltd., a professional manufacturer of hot melt glue spraying machinery, has built a strong reputation by delivering reliable Hot Melt Glue equipment and high-precision Hot Melt adhesive Machine systems. Guided by the principles of integrity, quality, and customer-first service, Saipu continues to support global appliance manufacturers with efficient and future-ready adhesive solutions.

Why Hot Melt Technology Is Essential for Household Appliances

Modern household appliances—such as refrigerators, washing machines, air conditioners, ovens, and small kitchen devices—require bonding solutions that can withstand temperature changes, vibration, humidity, and long-term use. Traditional fastening or solvent-based adhesives often fall short in efficiency, cleanliness, and environmental compliance.

The Hot Melt Adhesive Machine offers fast curing, strong bonding, and clean operation, making it ideal for automated appliance assembly lines. When paired with advanced Hot Melt Glue equipment, manufacturers can achieve precise adhesive control without compromising speed or consistency.

Key Applications in the Household Appliances Industry

1. Refrigerator Foaming, Sealing, and Caulking

In refrigerator manufacturing, foaming hot melt adhesives are widely used to seal cabinet joints and improve thermal insulation. A Hot Melt adhesive Machine applies adhesive evenly along seams before foaming, ensuring airtight sealing and reducing energy loss. Stable temperature control is essential to avoid adhesive degradation during continuous operation.

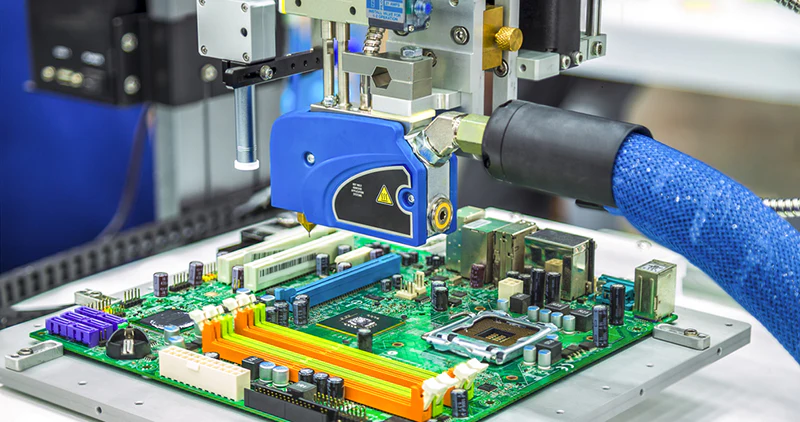

2. Electronic and Electrical Assembly

Household appliances contain control boards, sensors, wiring harnesses, and display modules. A Hot Melt Glue Machine secures components without damaging sensitive electronics. The clean, solvent-free process protects circuits while providing vibration resistance and mechanical stability.

3. Cable Fixing and Internal Structural Bonding

Using precision Hot Melt Glue equipment, manufacturers fix internal wiring, brackets, and insulation panels efficiently. Adhesive dots or lines can be applied exactly where needed, preventing movement during transport and long-term operation.

4. Decorative Panel and Trim Bonding

For appliance housings and decorative elements, a Hot Melt adhesive Machine delivers smooth, uniform bonding that improves appearance while reducing rework caused by misalignment or weak adhesion.

How Saipu Hot Melt Systems Work

Saipu’s Hot Melt Glue Machine systems melt adhesive uniformly and maintain stable viscosity through intelligent temperature control. Advanced pumps and filtration systems ensure smooth flow, while modular spraying heads allow manufacturers to switch easily between bead, slot, or spray application modes.

The flexibility of Saipu’s Hot Melt Glue equipment makes it suitable for both high-volume refrigerator production and smaller electronic assembly lines. Each Hot Melt adhesive Machine is engineered for durability, easy maintenance, and long service life in demanding factory environments.

Industry Analysis: Hot Melt Adhesive Use in Household Appliances (2025)

| Application Area | Main Requirement | Traditional Method Limitation | Advantage of Hot Melt Systems |

| Refrigerator sealing | Airtight & thermal stability | Mechanical fasteners leak | Hot Melt Glue Machine ensures uniform sealing |

| Foaming insulation | Consistent bonding | Uneven adhesive spread | Hot Melt adhesive Machine improves insulation |

| Electronic assembly | Clean, safe fixation | Solvent damage risk | Hot Melt Glue equipment protects components |

| Cable management | Vibration resistance | Loose wiring over time | Stable adhesive fixing |

| Panel bonding | Aesthetic finish | High rework rate | Clean, precise application |

| Energy efficiency | Reduced heat loss | Inconsistent sealing | Improved appliance performance |

Advantages of Saipu Hot Melt Solutions

Precise temperature control for long production cycles

Energy-efficient melting for reduced operating cost

Modular design for easy cleaning and maintenance

Compatibility with automated appliance assembly lines

Stable performance in foaming hot melt applications

Professional after-sales service and technical support

By choosing Saipu’s Hot Melt Glue Machine, manufacturers gain a reliable partner focused on quality, efficiency, and long-term value.

Frequently Asked Questions (FAQ)

Q1: Are hot melt adhesives safe for electronic components?

Yes. When applied using a Hot Melt adhesive Machine, the process is clean, solvent-free, and temperature-controlled to protect sensitive electronics.

Q2: Can one system handle both sealing and electronic assembly?

With the right configuration, Saipu’s Hot Melt Glue equipment can support multiple applications within the same factory.

Q3: How does hot melt improve refrigerator energy efficiency?

Uniform sealing and foaming reduce air leakage, improving insulation and lowering energy consumption.

Q4: Is maintenance complicated?

No. Saipu designs each Hot Melt Glue Machine for easy access, quick cleaning, and minimal downtime.

Conclusion

As household appliances become smarter, quieter, and more energy-efficient, manufacturers must rely on bonding technologies that deliver consistency and reliability. The Hot Melt Adhesive Machine has proven to be a powerful solution across refrigerator sealing, foaming, and electronic assembly applications.

With advanced engineering, stable performance, and dedicated service, Saipu’s Hot Melt Glue equipment and Hot Melt adhesive Machine systems help appliance manufacturers improve product quality while reducing production costs.

Call to Action

If you are looking to upgrade your household appliance production line with reliable, efficient, and environmentally friendly adhesive solutions, Saipu is ready to help. Explore how a customized Hot Melt Glue Machine solution can enhance sealing quality, assembly precision, and overall manufacturing performance.

For technical consultation or application testing, contact Dongguan Saipu Electromechanical Device Co., Ltd. and move confidently toward the next generation of appliance manufacturing.