Hot Melt Adhesive Machine Application In the capping industry

2026-01-06 10:45Enhancing Bonding Precision, Appearance, and Reliability for Modern Closures

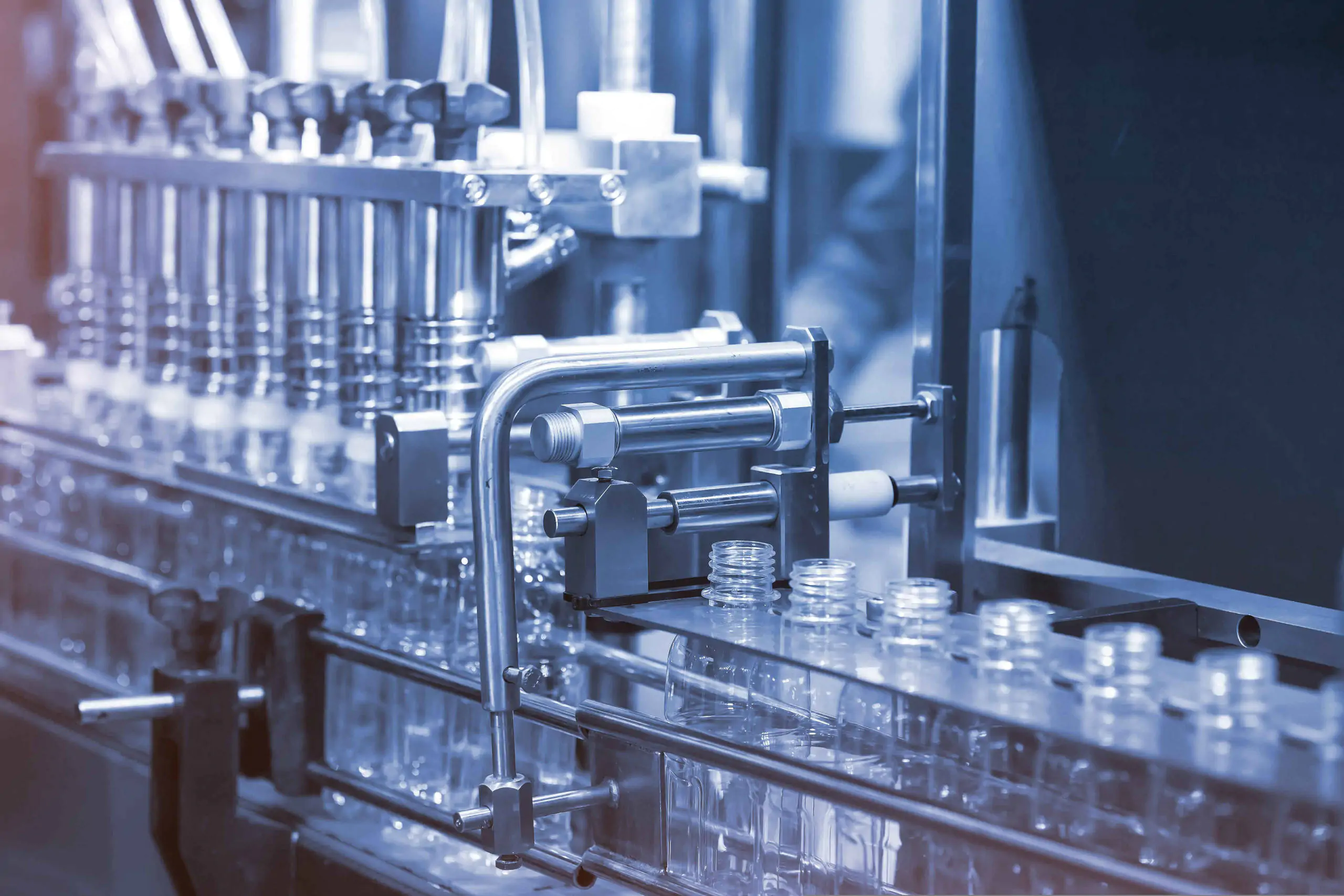

In today’s consumer-driven markets, product packaging is no longer just about protection—it is a direct extension of brand value. From cosmetic containers and premium liquor bottles to decorative accessories such as necklace pendants, caps and closures play a critical role in both functionality and aesthetics. Behind these seemingly small components lies a crucial manufacturing process: reliable bonding. This is where the Hot Melt Adhesive Machine in the capping industry has become an indispensable solution.

Dongguan Saipu Electromechanical Device Co., Ltd., a specialized manufacturer of hot melt adhesive application systems, has been deeply involved in the development of advanced Hot Melt Glue Machine solutions for capping applications. By combining mechanical precision, intelligent control systems, and application-specific engineering, Saipu continues to support manufacturers seeking higher efficiency, cleaner bonding, and consistent product quality.

The Growing Importance of Hot Melt Technology in the Capping Industry

Caps are widely used across industries, including cosmetics, food and beverage, spirits, personal care, and fashion accessories. In these applications, bonding must meet multiple requirements simultaneously: firm adhesion, clean appearance, high production speed, and material compatibility.

Traditional bonding methods often struggle to balance these demands. Solvent-based adhesives may introduce odors, long curing times, or environmental concerns. Mechanical fastening can compromise appearance or increase assembly costs. In contrast, a modern Hot Melt adhesive Machine offers a clean, fast, and highly controllable bonding solution.

Within the Hot Melt Adhesive Machine in the capping industry, hot melt adhesives are melted, accurately dispensed, and rapidly solidified, creating strong bonds without solvents. This makes hot melt technology particularly suitable for high-volume, appearance-sensitive capping processes.

Typical Applications of Hot Melt Glue Machines in Capping

Hot melt applicators—often referred to as hot peptizers in manufacturing environments—are widely used in the bonding of caps across multiple product categories:

Cosmetic caps: perfume bottles, skincare containers, makeup packaging

White wine and spirits bottle caps: decorative caps, security sleeves, top ornaments

Jewelry and accessories: necklace pendants, decorative end caps, fashion components

In these applications, the Hot Melt Glue Machine ensures precise glue placement, preventing overflow, stringing, or visible residue. This is critical for maintaining a premium product appearance.

Working Method of Hot Melt Adhesive Machines in Capping Applications

The working process of a Hot Melt adhesive Machine in capping production is designed for speed, precision, and repeatability:

Adhesive Heating and Conditioning

The hot melt adhesive is heated to a stable, application-ready temperature, ensuring consistent viscosity.Precision Dispensing

Using controlled pumps and nozzles, the Hot Melt Glue equipment applies a precise amount of adhesive to the bonding area of the cap or pendant.Component Assembly

Caps are pressed onto bottles, containers, or decorative parts while the adhesive remains in a molten state.Rapid Solidification

As the adhesive cools, it quickly solidifies, creating a strong and clean bond without extended curing time.

This efficient workflow allows the Hot Melt Adhesive Machine in the capping industry to integrate seamlessly into automated or semi-automated production lines.

Industry Analysis: Performance Parameters in Capping Applications

| Performance Parameter | Traditional Adhesives | Hot Melt Glue Machine Solution |

| Bonding Speed | Slow | Very Fast |

| Appearance Cleanliness | Inconsistent | High and Uniform |

| Environmental Impact | Solvents, VOCs | Solvent-Free |

| Production Automation | Limited | Highly Compatible |

| Adhesive Waste | High | Low |

| Process Stability | Medium | High |

These advantages explain why the Hot Melt Glue Machine has become the preferred choice for manufacturers focused on quality consistency and operational efficiency.

Advantages of Hot Melt Adhesive Machines in the Capping Industry

The use of a Hot Melt Adhesive Machine in the capping industry delivers multiple operational and commercial benefits:

Strong and reliable bonding, even on smooth or decorative surfaces

Excellent aesthetic control, critical for premium packaging

High production efficiency, suitable for mass manufacturing

Wide material compatibility, including plastics, metals, glass, and decorative elements

Cleaner working environment, supporting sustainability goals

For manufacturers of cosmetics and spirits, where brand image is paramount, the Hot Melt adhesive Machine helps ensure every product meets visual and functional expectations.

Saipu’s Competitive Strength in Hot Melt Capping Solutions

Dongguan Saipu Electromechanical Device Co., Ltd. brings more than equipment manufacturing to the table. The company offers application-driven solutions built around real production challenges.

Key strengths of Saipu’s Hot Melt Glue equipment include:

Tailored system design for different cap sizes, shapes, and materials

High-precision temperature and pressure control

Stable performance during long production runs

Durable components designed for industrial environments

Professional after-sales service and technical support

Every Hot Melt Glue Machine developed by Saipu reflects its commitment to “Credibility First and Customer First,” ensuring customers receive long-term value rather than short-term fixes.

Why Hot Melt Technology Outperforms in Decorative Capping

In applications such as necklace pendants or decorative bottle caps, even minor bonding defects can lead to product rejection. The Hot Melt Adhesive Machine in the capping industry excels by offering repeatable accuracy and minimal visual impact.

Compared with other bonding technologies, hot melt systems reduce rework, improve yield rates, and protect brand reputation—key considerations in competitive consumer markets.

Frequently Asked Questions (FAQ)

Q1: Can hot melt adhesive damage cosmetic or decorative surfaces?

No. When properly configured, a Hot Melt adhesive Machine applies adhesive precisely, avoiding overheating or surface damage.

Q2: Is hot melt bonding suitable for glass and metal caps?

Yes. Modern Hot Melt Glue equipment supports a wide range of materials, including glass and metal.

Q3: How easy is maintenance for hot melt systems?

Saipu designs each Hot Melt Glue Machine with easy maintenance in mind, featuring modular components and accessible cleaning points.

Q4: Can the system be integrated into automated capping lines?

Absolutely. The Hot Melt Adhesive Machine in the capping industry is ideal for integration with automated assembly and inspection systems.

Call to Action

As consumer products demand higher quality, better appearance, and faster production cycles, manufacturers must rethink their bonding technology. Dongguan Saipu Electromechanical Device Co., Ltd. invites capping and closure manufacturers to explore advanced Hot Melt Glue Machine solutions designed for modern production needs.

By choosing Saipu’s Hot Melt adhesive Machine, businesses can improve efficiency, reduce defects, and strengthen their competitive edge in global markets.

Conclusion

The Hot Melt Adhesive Machine in the capping industry has become a key enabler of reliable bonding, clean aesthetics, and efficient manufacturing. From cosmetic caps and white wine bottle closures to decorative pendants, hot melt technology delivers the performance today’s markets demand.

With strong technical expertise, application-focused design, and customer-oriented service, Saipu’s Hot Melt Glue equipment continues to support manufacturers seeking long-term growth and consistent quality. In an industry where details define success, the Hot Melt Glue Machine is a strategic investment—not just a production tool.