Chinese-Intelligent 2.5P PUR Glue Dispensing Machine: How Customization Unlocks Ultimate Efficiency in Green Packaging

2025-11-07 10:25Today, as the green wave sweeps across the globe, the packaging industry stands at a crossroads. Adopting eco-friendly materials like recyclable cardstock and water-based laminates has become an irreversible trend. However, a troubling "efficiency paradox" emerges: traditional bonding methods using white glue, paste, or solvent-based adhesives are not only slow-drying and offer insufficient strength but also fail to meet the demands of high-speed automated production lines. Often, the pursuit of "eco-friendliness" sacrifices efficiency, leading to increased overall costs and production bottlenecks.

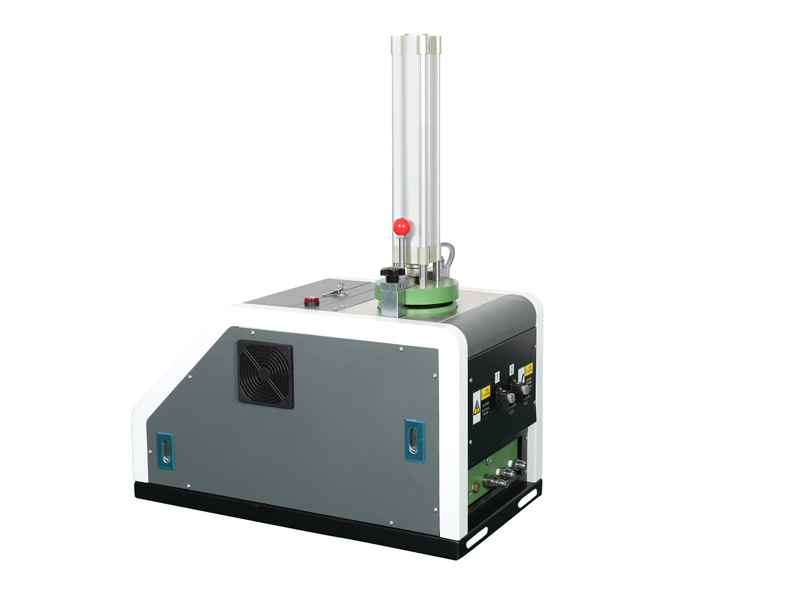

Must environmental responsibility and efficiency be mutually exclusive? The answer is no. The key to resolving this paradox lies in an innovative technology and its intelligent carrier—the 2.5P PUR hot melt adhesive dispensing equipment. As a deep practitioner in this field, Dongguan Saipu Electromechanical Device Co., Ltd. is providing new solutions for the green packaging industry in China and globally through its exceptional Custom 2.5P PUR Glue Dispensing System.

I. The Key to Breaking the Deadlock: Why 2.5P PUR Technology? Among numerous adhesive technologies, 2.5P PUR (Polyurethane Reactive—moisture-curing reactive polyurethane hot melt adhesive) stands out as the ideal choice for high-end green packaging. This is due to its irreplaceable technical advantages:

The Golden Capacity for Precision and Efficiency: The "2.5P" (approximately 2.5 gallons) medium-capacity design is a masterstroke. It meets the continuous 8-12 hour production

needs of most lines, avoiding interruptions for frequent adhesive changes, while significantly reducing the risk of pre-curing caused by prolonged heating in the melt tank compared to

larger capacity units. It perfectly balances efficiency with material stability. This Green Packaging PUR Adhesive Machine is built for sustained operation.

The Perfect Blend of Green and Robustness: PUR adhesive is inherently 100% solid content, solvent-free, and contains no VOCs (Volatile Organic Compounds), making it naturally

aligned with the environmental requirements of green packaging. More importantly, it reacts with trace moisture on the packaging material surface, forming an irreversible, ultra-strong

bond. Its resistance to high and low temperatures and fatigue performance far exceed those of traditional adhesives, making it particularly suitable for applications like Automatic Carton

Sealing PUR Machine that require long-distance transport or high durability.

II. Deep Customization in Chinese Intelligent Manufacturing: Turning "Universal Equipment" into a "Production Line Weapon"

Acquiring a standard machine from a leading China PUR Glue Machine Factory is just the starting point. The real value lies in deep, comprehensive customization services. This is the

core competitiveness of leading enterprises like Saipu. Their customization isn't merely about modifying dimensions; it's about comprehensive empowerment from dispensing and integration to control.

Customized Dispensing Solutions: From 'Adequate' to 'Optimal'

Saipu's engineers understand that different packaging structures require different adhesive strategies. For a Custom 2.5P PUR Glue Dispensing System, they tailor thespray head/valve based on the specific shape of the client's product—whether it's a delicate cosmetic carton or an appliance box needing reinforcement—achieving millimeter-precise adhesive patterns like fan, bead, dot, or spiral. This not only ensures impeccable bonding but also minimizes adhesive waste, directly saving the client significant costs on eco-friendly adhesive procurement. This Green Packaging PUR Adhesive Machine is thus endowed with a "smart brain" and "dexterous hands."

Customized Production Line Integration: Making the New Equipment a "Native Cell"

True automation isn't about a single machine's performance but the harmonious collaboration of the entire line. The Automatic Carton Sealing PUR Machine provided by Saipu possesses excellent integration capabilities. It can easily communicate and synchronize with the client's existing equipment, such as six-axis robots, conveyors, and assembly stations, enabling precise synchronous operation and truly achieving "unmanned" dark production in the packaging line. This exemplifies the transition of a China PUR Glue Machine Factory from equipment supplier to solution provider.Customized Intelligent Control: The "Flexible Soul" of One-Touch Switching

Addressing the trend of flexible production with small batches and high variety, Saipu equips its Precision PUR Melter for Eco-Packaging with high-performance touch-screen PLC control systems. Clients can pre-set dozens of parameters—such as adhesive volume, dispensing path, temperature, and pressure—for different packaging sizes and materials. When switching production tasks, operators need only a simple tap on the screen to seamlessly change all settings, reducing changeover time from tens of minutes to seconds and vastly improving production flexibility.

III. Case Study: High-Speed Gift Box Production Line for a Leading Smartphone Brand

Theoretical perfection requires practical validation. A classic case is the customized solution Saipu provided for a domestic first-tier smartphone brand.

This brand had stringent requirements for its high-end smartphone gift box packaging: the material was high-grade recyclable cardstock, requiring the attachment of a complex internal paper structure, and it had to fully comply with EU export environmental standards. Their original production line used solvent-based adhesives, which not only required lengthy drying times and posed environmental risks but also suffered from low efficiency in the manual labeling section, creating a production bottleneck.

Upon involvement, Saipu tailored a high-speed fully automatic production line integrated with a Custom 2.5P PUR Glue Dispensing System. The new Precision PUR Melter for Eco-Packaging ensured stable adhesive supply and precise temperature control; robotic arms equipped with custom dispensing heads applied PUR adhesive in perfect paths onto the internal structure, achieving instant, high-strength bonding.

The results were compelling:

Production Speed Increased by 50%: Eliminated drying time and synchronized the entire line's cycle time, significantly boosting output.

100% Compliance with Environmental Standards: The solvent-free, low-odor PUR adhesive easily passed the most stringent SGS tests.

Revolutionary Improvement in Bond Strength: The gift boxes remained intact even after long-distance transport and harsh environmental testing.

Significant Reduction in Overall Costs: Saved labor, reduced defect rates, and optimized adhesive usage.

Key Parameter Comparison Table for Green Packaging Dispensing Solutions

| Parameter | Traditional White Glue/Solvent Glue | Standard Hot Melt Equipment | Saipu Custom 2.5P PUR System |

| Curing Speed | Slow (minutes to hours) | Fast (seconds) | Very Fast (1-3 sec initial set) |

| Bond Strength | Medium, prone to aging | High, but poor temperature resistance | Very High, resistant to temp extremes & hydrolysis |

| Environmental | Contains VOCs/Solvents | Solvent-free, but poor recyclability | Solvent-free, 100% solids, supports material recycling |

| Line Adaptability | Poor, hard to automate | Good, but limited flexibility | Excellent, deep customization, seamless integration |

| Overall Cost | High hidden costs (energy, labor, waste) | Lower, but limited applications | Higher initial investment, but superior long-term ROI |

| Typical Use Cases | Low-speed, low-demand packaging | Medium-speed standard carton sealing | High-speed, high-quality Automatic Carton Sealing PUR Machine, premium boxes, eco-materials |

Frequently Asked Questions (FAQ)

Q1: Our factory currently uses traditional EVA hot melt adhesives. Is switching to a PUR system very complex and expensive?

A: Switching does require upfront planning and investment, but it's far less complex than often perceived. Saipu, as an experienced China PUR Glue Machine Factory, designs its Custom 2.5P PUR Glue Dispensing System with production line upgrades in mind. We assess your existing line and provide a complete retrofit plan including piping, interfaces, and electrical connections. While the initial equipment investment is higher than EVA, PUR's stronger adhesion often allows for less adhesive use. Combined with the benefits of increased efficiency and reduced waste, the Return on Investment period is typically much shorter than clients anticipate.

Q2: PUR adhesive requires strict moisture protection. Does this significantly increase our operational and maintenance costs?

A: This is a common concern regarding PUR technology. Saipu's Precision PUR Melter for Eco-Packaging incorporates comprehensive built-in protection. Our system features a sealed melt tank, a high-performance molecular sieve drying system, and moisture-proof hoses, creating a robust "moisture barrier." Following our standard operating procedures, daily maintenance is straightforward and does not incur significant additional costs.

Q3: Customized solutions often mean long lead times and high costs. How does Saipu address this?

A: We solve this challenge through an innovative model of "platform modules, customized combinations." Our Custom 2.5P PUR Glue Dispensing System is built on a mature modular platform. Most specific client needs can be met by configuring and optimizing our standard modules (e.g., valves, control systems). This greatly shortens design and manufacturing lead times and helps control costs, ensuring you receive a machine truly built for you within a reasonable timeframe.

Call to Action: Reshape Your Packaging Efficiency and Green Competitiveness Now

While your competitors may already be reducing costs and increasing efficiency through technological upgrades, waiting and watching is the biggest cost of all. Is your packaging line struggling with the conflict between efficiency and environmental goals?

We invite you to take the first step towards transformation with Saipu:

Get a Free Production Line Efficiency Diagnosis Report: Our experienced engineers will analyze the pain points in your current packaging process and provide preliminary optimization recommendations.

Avail Free Sample Testing Service: Send us your packaging materials, and we will use our Precision PUR Melter for Eco-Packaging to provide free sample testing—let the data and results speak for themselves.

Don't let outdated adhesive processes constrain your company's potential. Let us equip your products with packaging that is both green and highly efficient through a Custom 2.5P PUR Glue Dispensing System deeply tailored to your needs, and step together into the future of intelligent manufacturing.

Conclusion

At the convergence of green packaging and intelligent manufacturing, forces of Chinese Intelligent Manufacturing, represented by Dongguan Saipu, are decisively breaking the "curse" that environmental responsibility and efficiency are mutually exclusive. Through their deep understanding and excellent practice of the Custom 2.5P PUR Glue Dispensing System, they offer not just a Green Packaging PUR Adhesive Machine, but a key to unlocking ultimate efficiency and empowering a green future. Choosing to partner with Chinese Intelligent Manufacturing means choosing a path toward greater efficiency, sustainability, and competitiveness.