Beyond the Glue Tank: How Modern 30-Liter Hot Melt Machines Integrate into Smart Factory Systems

2025-10-29 15:30Dongguan Saipu Electromechanical Device Co., Ltd. Redefines Bonding Solutions for Medium-to-Large Production Lines with PLC Control and IIoT Technology

Introduction: When the "Glue Tank" Meets the "Smart Factory"

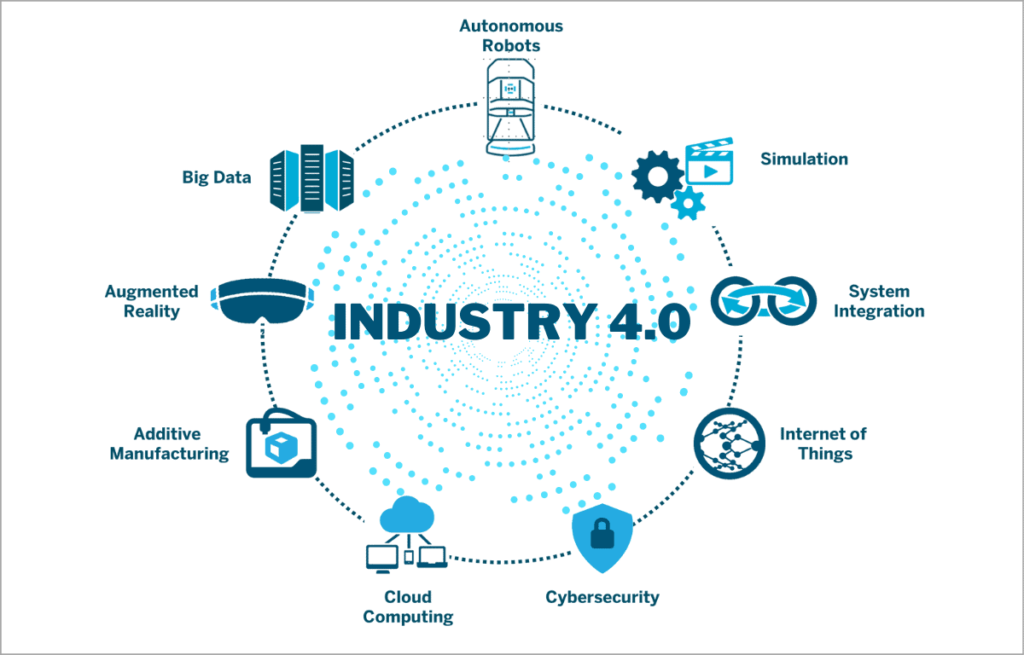

In traditional manufacturing, a Hot Melt adhesive Machine might be viewed merely as a "glue tank" for heating and dispensing adhesive. However, as the Industry 4.0 wave sweeps across the globe, this perception is being completely subversion. The challenge for today's manufacturers is no longer just bonding itself, but how to synchronize the bonding process with the digital, automated pulse of the entire smart factory. They need not be isolated equipment, but intelligent "bonding units" that can integrate into the production network, provide data, and be commanded remotely. It is in this context that the new generation 30-liter hot-melt glue machine from Dongguan Saipu Electromechanical Device Co., Ltd., with its advanced PLC-controlled adhesive system and connectivity capabilities, is evolving from a functional product into a revolutionary solution driving production line efficiency.

Chapter 1: The Call of the Era – Why Intelligent Bonding is Becoming Mandatory for Manufacturing

The competitive landscape in manufacturing has shifted from "scale competition" to "efficiency competition." According to reports from the authoritative market research firm Mordor Intelligence, the global industrial automation market is projected to continue expanding at a CAGR of over 9% until 2027. This indicates that the intelligent transformation is no longer an option but a necessity for survival.

For industries using industrial hot melt gluer equipment, such as packaging, automotive, and furniture, the hidden costs associated with traditional equipment are becoming increasingly apparent:

Information Silos: Traditional glue machines cannot upload data, requiring frequent manual checks for adhesive level and temperature, leading to opaque production status.

Downtime Risk: Inability to predict adhesive levels can lead to unexpected stoppages for refilling, disrupting the rhythm of the entire production line.

Quality Fluctuations: Reliance on manual experience for setting and adjusting parameters; temperature fluctuations can directly affect bond quality, causing batch quality issues.

High Management Costs: Lack of data support prevents precise energy management and production efficiency analysis.

A true smart hot melt machine is born to solve these very problems. It is no longer a passive executor but an intelligent node capable of perception, analysis, execution, and communication.

Table: Performance Analysis – Smart vs. Traditional Hot Melt Adhesive Machines

| Feature Dimension | Traditional Hot Melt Machine (Functional) | Saipu Smart 30L Hot Melt Machine (Intelligent) | Core Value for Smart Factory |

|---|---|---|---|

| Control Core | Analog Circuit / Simple Thermostat | High-end PLC-controlled adhesive system | Precise parameter adjustment, logical control, supports complex programming & automation linkage |

| Data Interaction | None | Supports data output (temp., level, status, fault codes) to MES/ERP | Breaks information silos, enables production visibility & traceability |

| Remote Monitoring | Requires on-site visual check | Remote monitoring & operation via Mobile App/PC | Reduces manual patrols, enables remote diagnostics & handling, improves response time |

| Temp. Control Accuracy | ±5°C ~ ±10°C | ±1°C (via advanced PLC-controlled adhesive system) | Ensures extreme consistency in bond quality, crucial for high-performance adhesives like PUR |

| Production Flexibility | Manual readjustment for product changeovers | Pre-set recipes allow one-touch switching | Rapid response to flexible production needs (small batches, high mix) |

| Predictive Maintenance | Reactive repair after failure | System monitors key component status, prompts preventive maintenance | Significantly reduces unplanned downtime, improves Overall Equipment Effectiveness (OEE) |

| Integration Capability | Works in isolation | Seamless integration with robots, conveyors, vision systems – part of an industrial hot melt gluer network | Becomes an organic component within a fully automated production line |

Chapter 2: Redefining the Core – The Intelligent Features of Saipu's 30L Smart Hot Melt Machine

Our 30-liter hot-melt glue machine was designed from the ground up with an "intelligence-first" philosophy. It is not just a medium-capacity hot melt glue tank; it is the "Bonding Brain" of your smart factory.

1. Precise Temperature Control: The Cornerstone of Intelligent Bonding

Temperature is the soul of hot melt adhesion. Our equipment employs multi-zone PID intelligent temperature control algorithms, ensuring temperature fluctuations are strictly maintained within ±1°C throughout the entire system – from the hot melt glue tank, through the hoses, to the spray gun. This extreme stability is vital for high-end adhesives like PUR (Polyurethane Reactive), which require precise activation temperatures. It guarantees highly consistent bonding performance with every application, eliminating quality risks rooted in temperature variance.

2. PLC Control & HMI: The Intelligent Command Center

At the heart of the machine lies a robust PLC-controlled adhesive system. Compared to traditional relay control, the PLC (Programmable Logic Controller) offers unparalleled reliability, flexibility, and precision.

One-Touch Operation: For different products, you can pre-set and store various working parameters (temperature, dispensing time, intervals, etc.) on the touchscreen. Switching production requires simply recalling the corresponding recipe, eliminating tedious manual adjustments, significantly reducing dependence on skilled operators, and preventing human error.

Fault Self-Diagnostics: The system continuously monitors operational status. If abnormalities like temperature deviation, motor overload, or communication loss occur, it immediately pops up clear alarm messages on the HMI and logs historical faults, guiding maintenance personnel to quick resolution.

3. Data Output & Remote Monitoring: The Bridge to Industry 4.0

This is the hallmark capability that distinguishes our smart hot melt machine from conventional units.

Data Transparency: The machine comes with standard communication interfaces (e.g., RS485, Ethernet, with options for Profinet, EtherCAT), enabling seamless transmission of real-time data—including tank level (estimated), current temperature, set temperature, operating status, runtime, fault information—to the factory's MES (Manufacturing Execution System) or cloud platform.

Mobile App Control: Managers don't need to be on the shop floor. They can monitor the real-time status of any Saipu machine worldwide via an authorized mobile app or web browser. The system can automatically push alarm notifications to their phones for low adhesive or faults, enabling "predictive refilling" and "remote early warning," minimizing production disruptions.

4. Automation Integration: Seamless Fit into Smart Lines

As a modern industrial hot melt gluer, it possesses robust external I/O (Input/Output) control capabilities. It can easily receive trigger signals from PLCs, sensors, or robots for precise timed or metered dispensing. Concurrently, it can output status signals like "Ready," "Working," "Fault," coordinating with peripherals like automated conveyors and robots to form a highly efficient, unmanned intelligent bonding workstation.

Chapter 3: Application Scenarios – How Intelligent Bonding Empowers Diverse Industries

Saipu's 30-liter hot-melt glue machine, with its stable large capacity and advanced intelligent features, plays a key role across numerous sectors:

Automotive Manufacturing: Integrated with robots for high-precision, complex-path automated dispensing in applications like car lamp assembly, windshield sealing, and interior trim attachment. The data traceability system meets stringent quality requirements.

High-End Packaging: On automated lines for moon cake boxes, tea boxes, premium cigarette cases, and high-end cartons, stable adhesive supply and rapid response ensure aesthetic appeal and strength. The recipe recall function perfectly adapts to frequent product changeovers.

Furniture & Building Materials: Used for edge banding and panel lamination, the hot melt glue tank's continuous supply supports long, uninterrupted production runs, while precise temperature control prevents edge lifting or warping, enhancing product quality.

Hygiene & Medical Products: On high-speed lines producing masks, protective clothing, diapers, and sanitary napkins, equipment reliability and stability are critical. Remote monitoring and Early warning function ensure highly efficient operation with nearly "zero unexpected downtime."

Chapter 4: Frequently Asked Questions (FAQ)

Q1: Our factory currently uses traditional equipment. Would upgrading to your smart hot melt machine be a complex process?

A: Rest assured, we have fully considered the ease of upgrade. Our 30-liter hot-melt glue machine offers standardized electrical interfaces and communication protocols. Our technical team provides comprehensive support to assist with integration into your existing line and commissioning, ensuring a smooth transition.

Q2: Won't the "smart" features of this machine make it very difficult to operate and maintain?

A: On the contrary, the goal of intelligence is "simplification." Our device features an intuitive graphical HMI. Complex traditional setups are replaced by "one-touch recipe recall"; frequent manual checks are replaced by "remote monitoring"; traditional fault-finding is replaced by "self-diagnostic prompts." It actually reduces the experience required for operation and makes maintenance more targeted.

Q3: Is the 30-liter hot melt glue tank capacity sufficient for continuous three-shift production?

A: The 30-liter capacity is a "sweet spot" proven suitable for medium-to-large production lines through extensive market validation. It provides long continuous operation, significantly reducing refill frequency. Combined with our "low-level remote alert" function, you can schedule refills during planned breaks (e.g., lunch, shift changes), completely avoiding production stoppages for refilling. For extremely high-consumption scenarios, we can also offer larger models or central feeding system solutions.

Q4: Does your PLC-controlled adhesive system support communication with third-party robots or PLCs?

A: Yes, this is a core philosophy of our equipment. We offer multiple industry-standard communication protocol options, enabling seamless integration with major robot brands (e.g., KUKA, Fanuc, ABB) and PLC systems (e.g., Siemens, Mitsubishi, Omron), ensuring it becomes an obedient and efficient intelligent component within your automated production line.

Conclusion & Call to Action

Industry 4.0 is not a distant concept; it is happening in every proactively evolving workshop. While your competitors might still struggle with unexpected downtime and quality fluctuations, you can already achieve visualized production data, remote management processes, and intelligent decision support with a Saipu Smart 30-liter hot-melt glue machine.

This machine is not just an upgrade to replace old equipment; it is a strategic investment in building the factory of the future. It represents a higher dimension of competitiveness: less downtime, lower energy consumption, greater consistency, and smarter management.

Act Now, Step into a Smarter Manufacturing Future!

We invite you to contact the sales engineering team at Dongguan Saipu Electromechanical Device Co., Ltd. for:

A personalized needs analysis to assess the potential for smart upgrades on your line.

A live online demonstration to see the intelligent features of this smart hot melt machine in action.

Free access to detailed technical documentation and success stories, showing how it creates value for peers.

Don't let your bonding process remain in the "glue tank era." Choose Saipu, and let us help you transform your bonding station into another efficient, reliable, and intelligent highlight within your smart factory.