Türkiye Woodworking Exhibition in October 2024

Dongguan Saipu Electromechanical Equipment Co., Ltd. Shines at Türkiye Woodworking Exhibition in October 2024

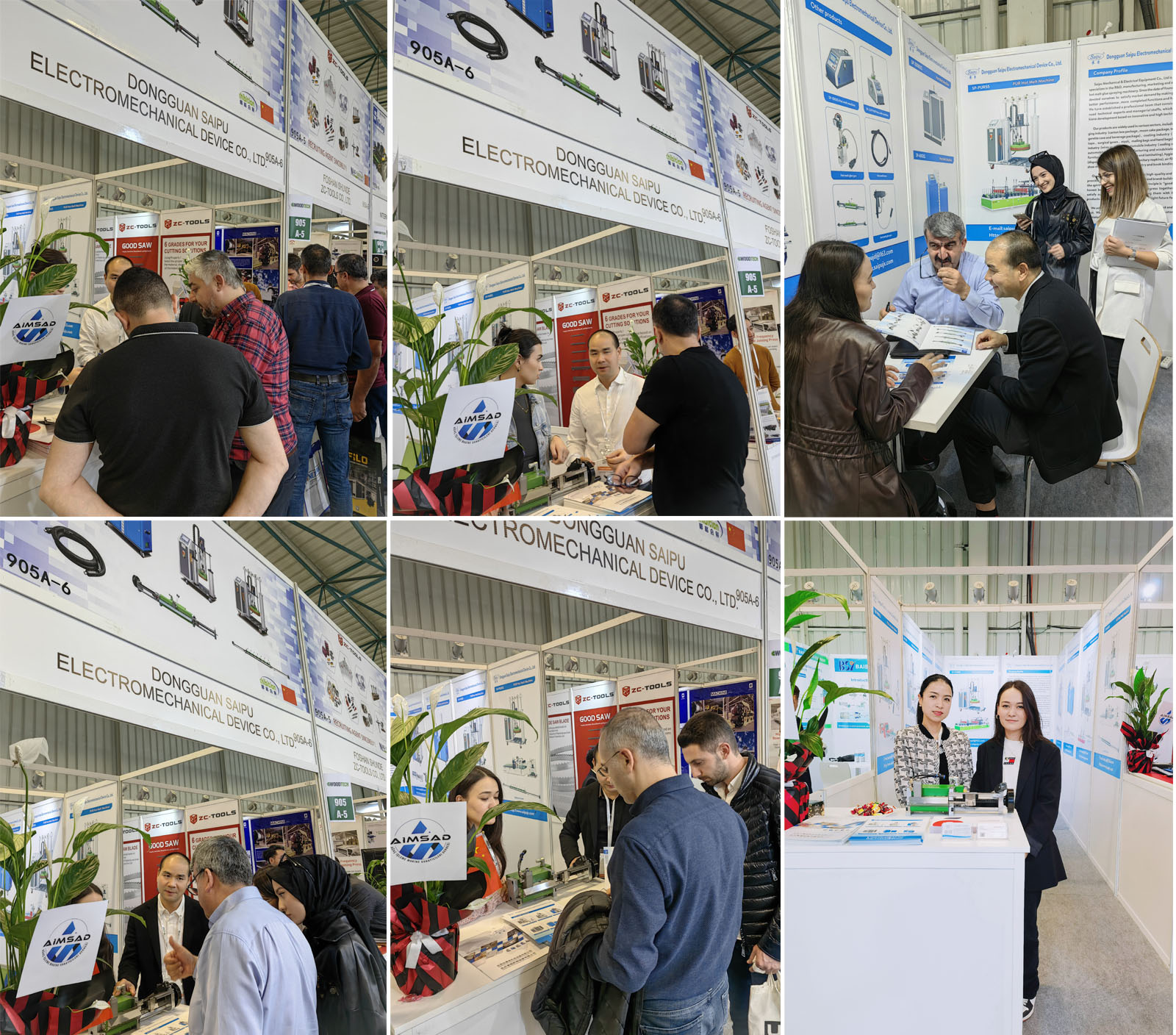

In October 2024, Türkiye ushered in a grand event of woodworking industry - Türkiye Woodworking Exhibition. This exhibition has attracted the attention of many related companies around the world, and Dongguan Saipu Electromechanical Equipment Co., Ltd. has actively participated in it. With its own technical strength and innovative products, it has shone brightly at the exhibition and gained many achievements and valuable opportunities.

Carefully prepared, stunning debut

For this Türkiye Woodworking Exhibition, Sepp Electromechanical began to make careful preparations months in advance. The company has established a professional exhibition team consisting of elite talents from various fields such as technology research and development, sales, and after-sales service, aiming to comprehensively showcase the company's strength and product advantages, and provide professional and thoughtful services to global customers. In terms of booth design, Saipu Electromechanical has abandoned the traditional complex style and adopted a simple yet technologically advanced design concept. With bright color combinations and an open space layout, it creates a comfortable and convenient communication environment, allowing every visitor to easily understand product information and engage in in-depth communication with staff.

At the exhibition site, Saipu Electromechanical made a heavyweight appearance with multiple star products specially designed for the woodworking industry. Among them, the latest hot melt adhesive machine attracted a large number of viewers to stop and watch as soon as it was unveiled. This hot melt adhesive machine integrates the company's independently developed intelligent temperature control and precise spraying system. The intelligent temperature control system utilizes high-precision temperature sensors to sense the temperature of the adhesive in real time and accurately. Based on different working environments and adhesive characteristics, it automatically adjusts the power of the heating element to ensure that the adhesive is always at the optimal working temperature. The fluctuation range is controlled within a very small range, greatly improving the coating uniformity and bonding strength of the adhesive. The precision spraying system optimizes the structure of the hot melt adhesive nozzle and redesigns the internal flow channel to make the glue more stable and uniform during spraying, achieving precise control over the amount and range of glue spraying. Whether it is fine woodworking art bonding or large board splicing operations, it can easily cope with them, providing strong guarantees for woodworking enterprises to improve production efficiency and reduce production costs.

Saipu Electromechanical's coating machine also attracted a lot of attention at the exhibition. The device is equipped with a newly upgraded high-speed stable unwinding and coating thickness intelligent adjustment device. The high-speed stable unwinding device solves the problems of coil jamming and uneven tension that are prone to occur in traditional unwinding processes. Through advanced tension control systems and high-precision mechanical transmission components, it can ensure that the coil remains stable and uniform during unwinding, providing a stable material supply for subsequent coating operations. The intelligent coating thickness adjustment device utilizes advanced sensor technology and automation control system. Operators only need to input the required coating thickness parameters on the equipment control panel, and the equipment can automatically adjust the gap and pressure of the coating roller, achieving precise control of the coating thickness. The error can be controlled within a very small range, meeting the diverse and high-precision requirements of the woodworking industry for surface coating treatment of boards. Whether it is board coating in furniture manufacturing or surface treatment in wooden door production, it can demonstrate excellent performance.

Customer negotiations have yielded remarkable results

Throughout the exhibition period, the booth of Saipu Electromechanical was crowded with people and lively. Professional buyers such as woodworking machinery manufacturers, furniture manufacturers, and building materials distributors from multiple regions including Europe, Asia, the Middle East, and Africa have come to engage in in-depth exchanges and negotiations with the staff of Sepp Electromechanical. According to incomplete statistics, during the exhibition, Saipu Electromechanical received over X groups of professional visitors and collected nearly X pieces of potential customer information, including well-known enterprises and large purchasers in the industry.

In the process of communicating with customers, the team members of Saipu Electromechanical, with solid professional knowledge and rich industry experience, introduced the performance characteristics, technical advantages, application cases, and perfect after-sales service system of the product to customers in detail. For every question raised by customers, the staff patiently answers, striving to provide customers with a comprehensive and in-depth understanding of the product. After listening to the introduction, many customers showed a strong interest in Saipu Electromechanical's products and conducted product testing on the spot. A large furniture manufacturing enterprise from Europe, after conducting strict on-site tests on hot melt glue machines and coating machines, praised the performance of the equipment and immediately reached a preliminary purchase intention with Sepp Electromechanical, planning to introduce multiple equipment to its multiple furniture production lines to improve production efficiency and product quality. According to statistics, during the exhibition, Saipu Electromechanical signed intention cooperation agreements with multiple customers, with a cumulative intention order amount exceeding [X] million yuan, laying a solid foundation for the company to further expand into overseas markets.

Exchange learning, insight into trends

Türkiye Woodworking Exhibition is not only a platform for product display and trading, but also an important window for all parties in the woodworking industry to exchange and learn and insight into the development trend of the industry. During the exhibition, the team of Saipu Electromechanical actively participated in various industry forums, seminars, and technical exchange activities, discussing the current development status, challenges, and future trends of the woodworking industry with peer enterprises, experts, and scholars from around the world.

Through in-depth communication with various parties, Saipu Electromechanical has keenly captured that the woodworking industry is rapidly developing towards intelligence, green environmental protection, and high efficiency and energy conservation. With the increasing demand of consumers for the quality and environmental performance of home products, woodworking enterprises have also put forward higher requirements for the intelligence level, energy utilization efficiency, and environmental performance of production equipment. After attending an industry forum, the head of technical research and development at Saipu Electromechanical said, "This exhibition has made us deeply realize the urgency and necessity of the industry's intelligent transformation. In the future, we will increase our research and development investment in intelligent control technology, energy-saving and environmentally friendly material applications, continuously optimize product performance, launch more innovative products that meet market demand, help customers enhance their competitiveness, and promote the sustainable development of the entire woodworking industry

In addition, Saipu Electromechanical has reached preliminary cooperation intentions with some upstream and downstream enterprises during the exhibition, planning to carry out deep cooperation in raw material supply, technology sharing, joint research and development, etc., further improving the industrial chain layout and enhancing the company's comprehensive strength. Through close cooperation with suppliers, Saipu Electromechanical will ensure stable supply and quality improvement of raw materials, and reduce production costs; Collaboration with peer enterprises in technology sharing and joint research and development can help companies absorb and learn from advanced technologies and experiences in the industry, accelerate product innovation, and launch more competitive products.

The successful participation of Türkiye Woodworking Exhibition in October 2024 is a valuable experience for Dongguan Sap Electromechanical Equipment Co., Ltd. to show its strength, expand the market, learn and exchange. The company will take this opportunity to continuously increase research and development investment, improve product quality and service level, actively expand overseas markets, strengthen cooperation and communication with global customers, and strive to build the Sepp brand into a well-known brand in the global woodworking electromechanical equipment field, contributing more to promoting China's woodworking electromechanical equipment industry to the world. In the future development path, Saipu Electromechanical will continue to uphold the concept of innovation, efficiency, and win-win, and work together with partners in the global woodworking industry to create a better future.