Successful Case of Dongguan Saipu Electromechanical Equipment Co., Ltd.'s Hot Melt Adhesive Spraying Machinery in the Packaging Industry

Successful case of Dongguan Saipu Electromechanical Equipment Co., Ltd.'s hot melt adhesive spraying machinery in the packaging industry

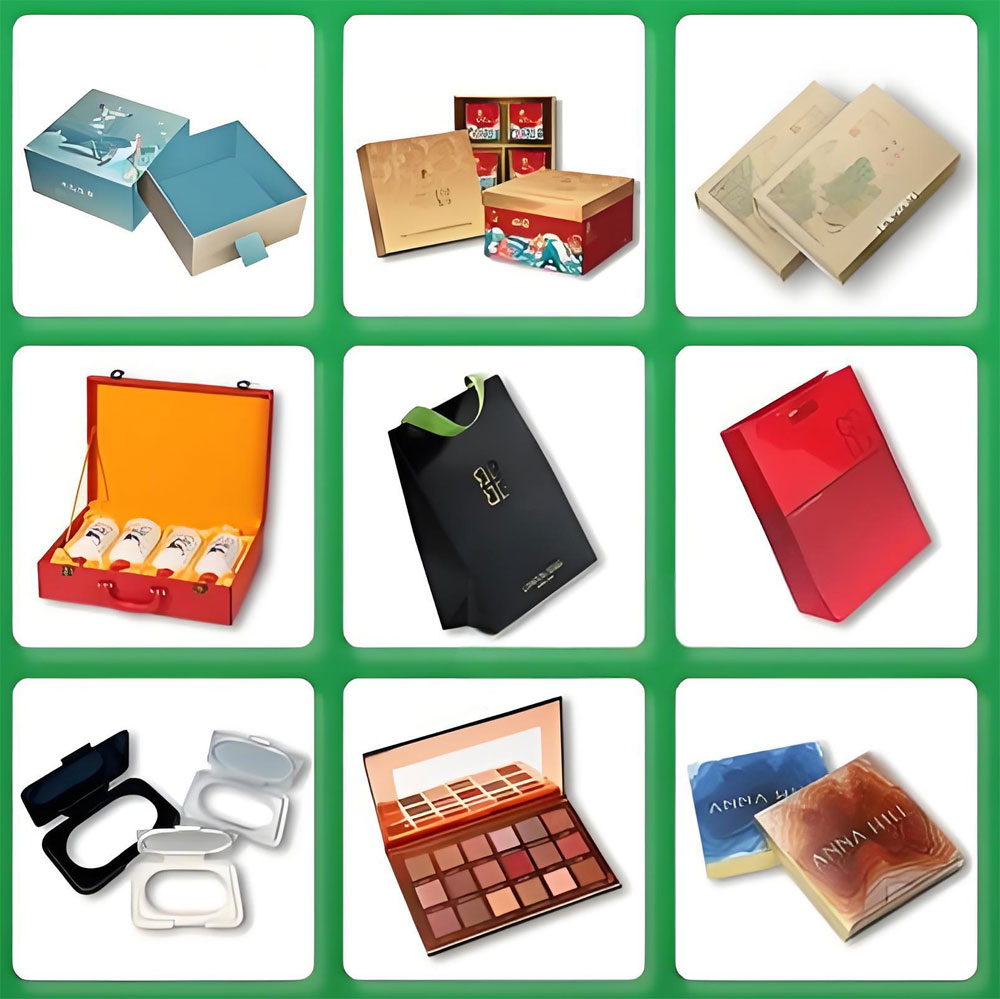

In the packaging industry, the efficiency and precision of hot melt adhesive spraying machinery are crucial. Dongguan Saipu Electromechanical Equipment Co., Ltd. focuses on the research and development, manufacturing of hot melt adhesive spraying and coating machinery. Its products have helped enterprises achieve production upgrades in multiple sub fields such as cardboard packaging, mooncake packaging, tea boxes, cigarette boxes, and beverage packaging.

Carton packaging: efficient sealing, reducing costs

A large logistics packaging enterprise needs to handle a massive amount of cardboard boxes every day. In the past, manual sealing or traditional sealing equipment was used, which had low efficiency, serious glue waste, and unstable sealing strength. The cardboard boxes were prone to cracking during transportation. After the introduction of the hot melt adhesive spraying machine from Sepp Electromechanical, the situation has greatly improved. The hot melt glue machine of this equipment is equipped with a specially designed gear pump with a large dispensing volume, which ensures stable glue dispensing and can adapt to high adhesion glue dispensing operations, meeting the rapid adhesive coating requirements for large areas of cardboard boxes. The independent suspension system of the gear pump saves time and is convenient for maintenance and repairs, reducing downtime. The fully open flow control valve ensures the efficiency of the pump glue while solving the problem of excessive instantaneous glue pressure. According to feedback from the company, the use of Sepp equipment has increased the efficiency of box sealing by 60%, reduced the amount of glue used by about 30%, greatly reduced production costs, significantly improved the quality of box sealing, and significantly reduced the rate of transportation damage.

Mooncake packaging: exquisite fit, improving quality

A well-known mooncake production enterprise has extremely high requirements for the beauty and sealing of mooncake packaging. The hot melt adhesive spraying solution provided by Saipu Electromechanical lies in precise coating control. The temperature control system of its hot melt adhesive machine adopts PID digital temperature control, which heats evenly and prevents the glue from carbonizing, ensuring the best bonding performance of the glue. For the folding and pasting parts of mooncake boxes, the equipment can accurately spray an appropriate amount of glue, making the packaging paper and paper box tightly adhere without glue overflow. This not only improves the beauty of the packaging, but also extends the shelf life of mooncakes due to good sealing. The company stated that since using the Saipu hot melt adhesive spraying machine, the product defect rate has decreased by about 15%. Due to the exquisite packaging, the product is more competitive in the market and sales have steadily increased.

Tea box packaging: moisture-proof and sealed, retaining tea aroma

Tea has strict requirements for moisture resistance and sealing of packaging. Before using the hot melt adhesive spraying equipment of Saipu Electromechanical, a certain tea brand often caused the tea boxes to become damp and spoiled due to poor sealing. Saipu's hot melt glue machine uses optimized nozzle design during the gluing process to evenly and accurately apply hot melt glue to the sealing and splicing areas of tea boxes, forming a firm and tight seal. The built-in dual temperature control of the device ensures high safety and stable application of glue at the appropriate temperature. After actual testing, the tea box packaged with Sepp equipment has improved its moisture resistance by about 40% compared to before in the same environment, effectively preserving the aroma and quality of tea, reducing economic losses caused by tea spoilage, and significantly improving customer satisfaction.

Cigarette box packaging: high-speed, precise, and stable production

The cigarette packaging production line has fast speed and high precision requirements. A large tobacco enterprise, facing the dual challenges of capacity improvement and quality control, chose Saipu Electromechanical's hot melt adhesive spraying machinery. This device has high-speed and stable spraying performance, and can efficiently cooperate with cigarette box packaging production lines. Its modular design allows for easy replacement of different types of gear pumps or reflux valves, adapting to the diverse adhesive requirements during cigarette packaging. Under high-speed operation, the precision of glue spraying can still be guaranteed, and the glue position and dosage of each cigarette box are highly consistent, ensuring the quality stability of cigarette box packaging. The production efficiency of the enterprise has been improved by about 50%, and the scrap rate has been controlled at an extremely low level, effectively ensuring the smooth progress of large-scale production.

Beverage packaging: hygienic and reliable, adaptable to various needs

In the field of beverage packaging, hygiene and safety, as well as adaptability to different packaging materials, are key factors. Saipu Electromechanical's hot melt adhesive spraying machinery is made of materials that comply with food contact safety standards, ensuring that the adhesive does not contaminate beverages during the spraying process. For beverage packaging made of different materials such as plastic bottles and cans, the equipment can flexibly adjust the spraying parameters according to the packaging shape and material characteristics. In the labeling process of plastic bottles, by precisely controlling the spraying amount and position of hot melt adhesive, the label is firmly attached to the bottle body and is not easily detached in complex environments such as high temperature and humidity. After adopting Sepp equipment, a beverage production enterprise significantly reduced the number of packaging production line failures and greatly improved production stability. At the same time, due to reliable packaging quality, the return rate of products in market circulation decreased by about 20%.

Dongguan Saipu Electromechanical Equipment Co., Ltd.'s hot melt adhesive spraying machinery, with advanced technology and reliable performance, has brought tangible benefits to various sub sectors of the packaging industry, becoming a powerful partner for many enterprises to optimize production and enhance competitiveness.